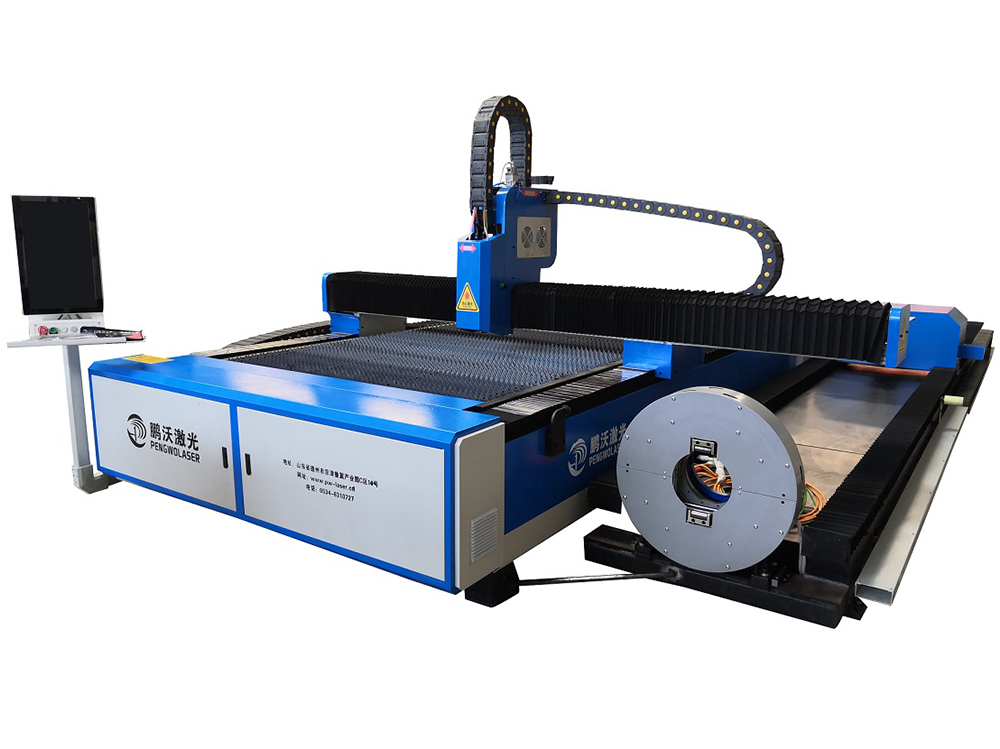

Fiber laser plate and tube integrated machine

High processing efficiency.

Rack and pinion drive system

Rack and pinion drive system, professional pipe cutting CNC system, high precision, full function, easy to use, simple operation.

Automatic full stroke pneumatic chuck

One-click clip opening, automatic centering,Three times faster than an electric chuck,Reduce loading and unloading waiting time;Pneumatic clamping, clamping force is large and constant, heavy tube does not loose and does not slip, to ensure cutting accuracy;

Heavy duty welded bed is durable

Made of welded heavy steel plates, High speed operation without jitter; High mechanical strength, not easy to deformation;

Bed weight, machine vibration is small, good shock resistance, to ensure the improvement of cutting accuracy: stomach reinforcement is set inside the bed, increase the strength and tensile resistance of the bed, effectively avoid deformation of the bed;

Heavy duty pneumatic chuck with large diameter

Self-centering chuck, fast centering clamping, fast automatic loading and unloading stone clamping without deformation, large clamping force, high clamping accuracy, long service life;Easy to handle heavy pipe stable clamping, improve work efficiency.

High speed switching table

Double table parallel exchange,Intelligent control switching motor,The machine can complete the exchange in 15 seconds at the fastest.Large transfer power, strong overload capacity;

Dual electric diao zone movement, intelligent safety, positioning accuracy: increase the track brush, platform exchange can clean up the residual waste on the car head.Make the bed run more smoothly.

Extreme cutting for flexible penetration

Knob type focus adjustment, fine adjustment, high flexibility;

Good sealing, high stability, speed perforation, cutting;

Strong cutting force, complete the plate cutting of different thickness and material;

Collimation and focusing are made of composite lenses, with the best optical quality and cutting effect;

Specification

FAQ

The edge of cutting surface of plate and tube machine is seriously fused.

Laser output power is too large, laser cutting speed is too slow, auxiliary pressure is small, nozzle design is unreasonable

Sheet-tube machine. Alarm on cutting?

Software not working, host loose

Not turning on the cooling system resulted in excessive temperature in the laser cavity

The water pressure in the cooling system is too low and the water level is insufficient

Can't turn on the laser power?

The emergency stop switch is closed

Laser power supply damaged

Plate and tube integrated cutting machine, protective mirror pollution is very fast what reason?

1. Waste residue: It is mainly due to improper parameter setting, resulting in cutting waste residue backsplashing onto the lens. It can be solved by adjusting the process parameters of cutting or piercing, such as follow height, cutting pressure, laser pulse parameters, etc.

2. Oil stains or dust: auxiliary gas itself or gas circulation pipeline is polluted. It can be controlled by adding a filter device to filter oil or dust.

3. Water mist: generally caused by too large temperature difference. The ambient temperature is too high, and the cutting gas temperature is too low. The dew formation of the protective mirror in the ambient temperature can be properly adjusted so that the temperature of the two is about the same to solve the problem.

Plate and tube cutting, carbon steel heating reason?

1. cutting gas flow is small, can not be fully cooled on the copper nozzle. High pressure nitrogen gas can be used as auxiliary gas, high pressure nitrogen cooling effect is good.

2. No copper nozzle is used for cooling gas. ADAPTS the copper nozzle cooling gas can reduce the copper nozzle heat.

3. High focus cutting, laser easy to hit the small nozzle, so that the nozzle overheating. It is necessary to adjust the focus or increase the nozzle diameter when the nozzle is not hot.

4. Carbon steel in cutting, oxidation reaction, produce a lot of heat. This situation is unavoidable, and the distance between the nozzle and the material can be adjusted appropriately.