Other sheet metal equipment series

-

60w laser marking machine

The working principle of the laser coding machine is to gather the laser at a very high energy density on the surface of the object to be engraved. By burning and etching, the material on the surface is vaporized, and the effective displacement of the laser beam is controlled.

According to the different marking forms, laser marking equipment can be divided into two types: marking type and dot matrix type. At present, most laser coding equipment in the market is marked, but Markon’s laser coding equipment is using a new lattice technology – lattice resident technology. Marking laser machine is mainly to mark the character of the track completely scratched out, and dot-matrix laser machine is to mark the character of some important track points scratched out. Thus, with the same energy, the new dot-matrix laser printer prints faster.

-

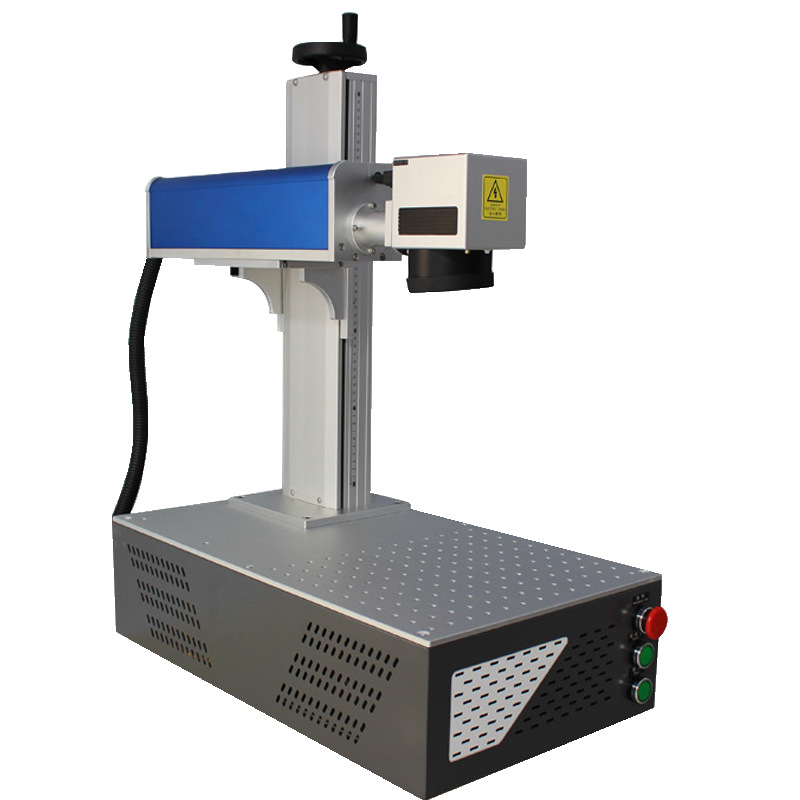

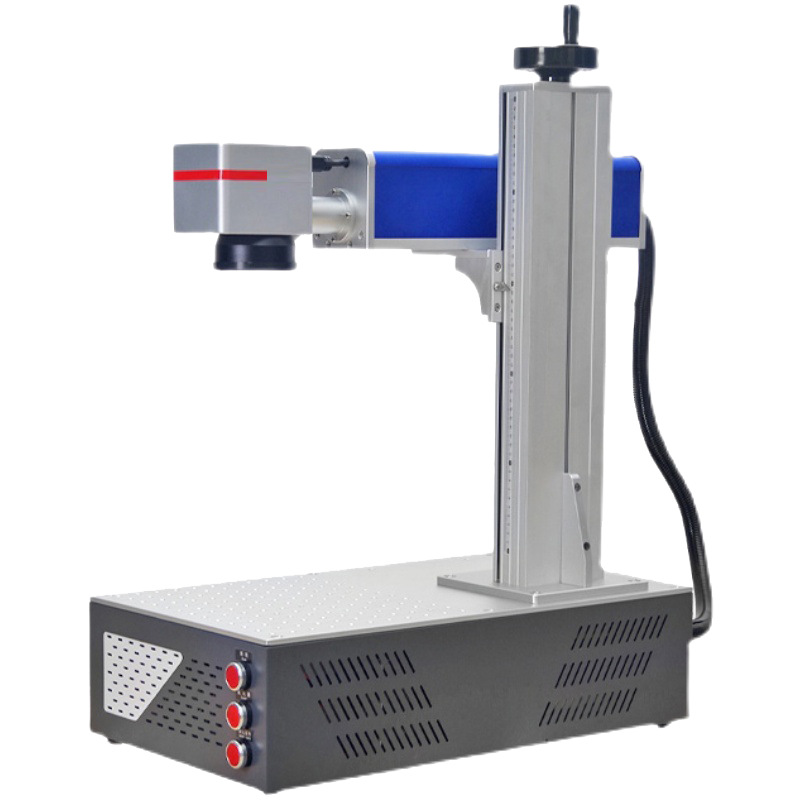

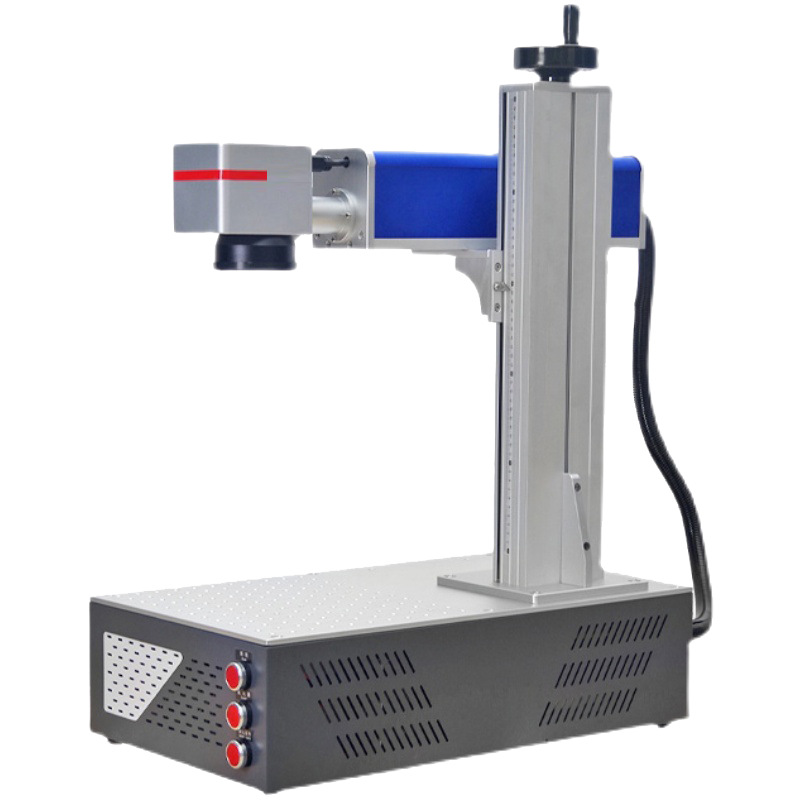

Desktop optical fiber marking machine

The working principle of the laser coding machine is to gather the laser at a very high energy density on the surface of the object to be engraved. By burning and etching, the material on the surface is vaporized, and the effective displacement of the laser beam is controlled.

According to the different marking forms, laser marking equipment can be divided into two types: marking type and dot matrix type. At present, most laser coding equipment in the market is marked, but Markon’s laser coding equipment is using a new lattice technology – lattice resident technology. Marking laser machine is mainly to mark the character of the track completely scratched out, and dot-matrix laser machine is to mark the character of some important track points scratched out. Thus, with the same energy, the new dot-matrix laser printer prints faster.

-

Two axis rubber roller rolling machine

This machine is an automatic two-axis plate winding machine, mainly used in the operation process of bending, at room temperature, the plate winding machine can be rolled into a cylindrical shape, punching plate round – hole round – section arc.

The upper roll is lifted and pressed by the motor through the reducer, transmission shaft, worm gear and worm pair, screw nut pair to transfer power, resulting in bending deformation of the steel plate. Coil drive through the main motor through the main reducer, open gear drive roller rotation, and become the driving roller when rolling plate. Because the lower roller elevation is unchanged, it is easy to feed and operate. Is a very general equipment, is the boiler, shipbuilding, petrochemical, cement, electric machine manufacturing of the main key equipment. The equipment has the advantages of simple structure, compact, convenient operation and high efficiency. The product roundness deviation is less than 0.5mm, the lower roll of the winding machine adopts hydraulic cylinder, which can not only ensure the smooth movement process, but also stable pressure during the rolling process, so as to ensure that the distance between the lower roll and the upper roll is constant. In the whole product forming process, the material deformation degree of each smiling distance is less than 0.5mm

-

Small one-piece code machine metal stainless steel nameplate engraving machine, portable fiber laser marking machine

The working principle of the laser coding machine is to gather the laser at a very high energy density on the surface of the object to be engraved. By burning and etching, the material on the surface is vaporized, and the effective displacement of the laser beam is controlled.

According to the different marking forms, laser marking equipment can be divided into two types: marking type and dot matrix type. At present, most laser coding equipment in the market is marked, but Markon’s laser coding equipment is using a new lattice technology – lattice resident technology. Marking laser machine is mainly to mark the character of the track completely scratched out, and dot-matrix laser machine is to mark the character of some important track points scratched out. Thus, with the same energy, the new dot-matrix laser printer prints faster.

-

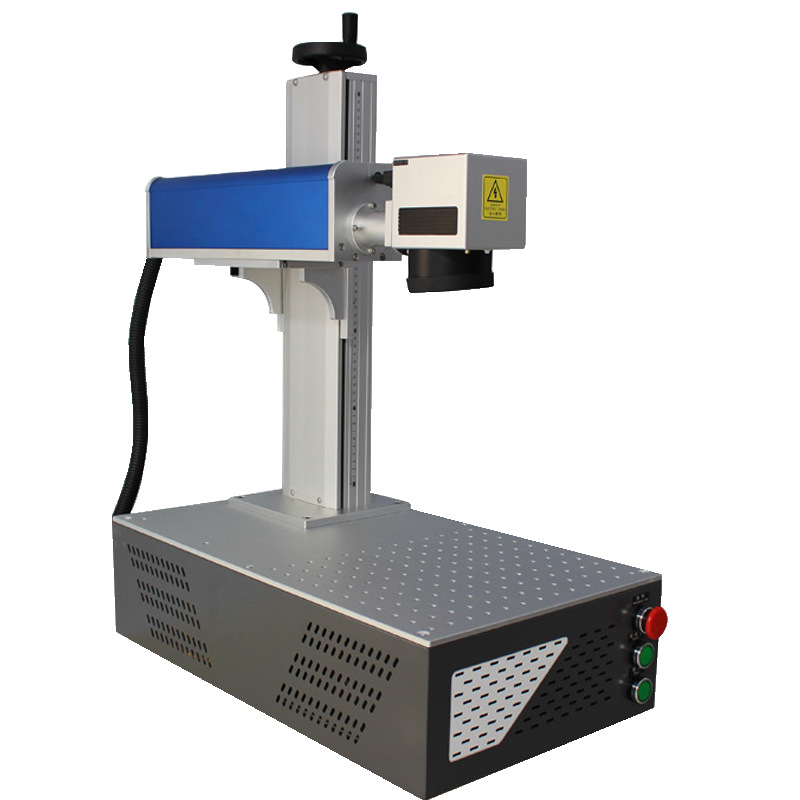

Fiber laser marking machine

The working principle of the laser coding machine is to gather the laser at a very high energy density on the surface of the object to be engraved. By burning and etching, the material on the surface is vaporized, and the effective displacement of the laser beam is controlled.

According to the different marking forms, laser marking equipment can be divided into two types: marking type and dot matrix type. At present, most laser coding equipment in the market is marked, but Markon’s laser coding equipment is using a new lattice technology – lattice resident technology. Marking laser machine is mainly to mark the character of the track completely scratched out, and dot-matrix laser machine is to mark the character of some important track points scratched out. Thus, with the same energy, the new dot-matrix laser printer prints faster.

-

W11-12×3000 symmetrical up-regulating three-roll plate coiler

This machine is an automatic two-axis plate winding machine, mainly used in the operation process of bending, at room temperature, the plate winding machine can be rolled into a cylindrical shape, punching plate round – hole round – section arc.

The upper roll is lifted and pressed by the motor through the reducer, transmission shaft, worm gear and worm pair, screw nut pair to transfer power, resulting in bending deformation of the steel plate. Coil drive through the main motor through the main reducer, open gear drive roller rotation, and become the driving roller when rolling plate. Because the lower roller elevation is unchanged, it is easy to feed and operate. Is a very general equipment, is the boiler, shipbuilding, petrochemical, cement, electric machine manufacturing of the main key equipment. The equipment has the advantages of simple structure, compact, convenient operation and high efficiency. The product roundness deviation is less than 0.5mm, the lower roll of the winding machine adopts hydraulic cylinder, which can not only ensure the smooth movement process, but also stable pressure during the rolling process, so as to ensure that the distance between the lower roll and the upper roll is constant. In the whole product forming process, the material deformation degree of each smiling distance is less than 0.5mm

-

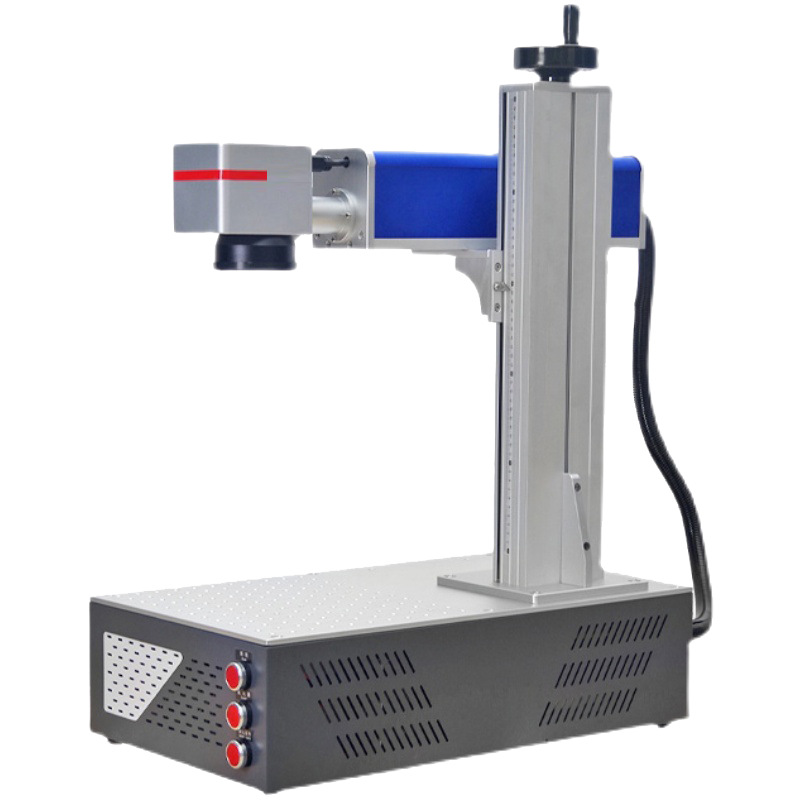

Desktop optical fiber marking machine

The working principle of the laser coding machine is to gather the laser at a very high energy density on the surface of the object to be engraved. By burning and etching, the material on the surface is vaporized, and the effective displacement of the laser beam is controlled.

According to the different marking forms, laser marking equipment can be divided into two types: marking type and dot matrix type. At present, most laser coding equipment in the market is marked, but Markon’s laser coding equipment is using a new lattice technology – lattice resident technology. Marking laser machine is mainly to mark the character of the track completely scratched out, and dot-matrix laser machine is to mark the character of some important track points scratched out. Thus, with the same energy, the new dot-matrix laser printer prints faster.

-

Symmetrical up – adjustable three – roll coiling machine

Hydraulic three-roll plate coiling machine: This machine is an up-regulated symmetrical three-roll plate coiling machine, which can roll metal plates into circular, curved and conical workpieces. The two lower rollers are active rollers, and the upper rollers are driven rollers. Widely used in shipbuilding, boiler, aviation, hydropower, chemical, metal structure and machinery manufacturing industries.This machine is suitable for bending deformation of metal plate, can be rolled round, curved and a certain range of conical workpiece, plate end prebending function, the model of the two lower roller for the active roller can move horizontally, the upper roller for the driven roller can move up and down, the transmission shaft is connected by the universal shaft.

-

Automatic CNC Angle flange production line

CNC Angle steel flange production line adopts the cooperation of CNC system and stamping machinery to complete the punching and cutting action of Angle steel, forming a complete set of flexible automatic stamping production line, stamping workers are liberated from monotonous heavy and dangerous working state, to ensure safety and improve production efficiency. CNC Angle steel flange production line system is a special system developed by our company on the basis of industrial computers of famous domestic brands. The hardware part has strong anti-seismic and anti-interference ability, the machine tool with centralized lubrication system can adapt to long time work, stable and efficient performance; Precision servo motor drive, fast speed, short response time, large torque, accurate control, ensure the feeding processing precision, good performance; Guide rail imported from Taiwan, high bearing capacity, good guidance; Adopt high precision rack imported from Taiwan, accurate and stable feeding; CNC Angle flange production line with pneumatic clamp, to prevent the Angle steel slippage in the process of driving, can fully ensure the clamping force.

-

Nc Angle steel flange production line

CNC Angle flange production line has strong rigidity, compact structure, optimized discharge, shear free function, high material utilization rate; Punching, cutting, automatic, high production efficiency; Computer Chinese interface, easy to operate, can display the workpiece graphics; When compiling the program, only need to input the size of the workpiece, the distance, the number of work can be simple programming, but also can directly use the program data generated by the lofting software. A number of measures have been taken in the production line of NC Angle steel flange to solve the difficulty of feeding and the error of alignment caused by Angle steel bending. PLC, industrial computer control, servo motor feeding, high efficiency, stable working accuracy; The key liquid, gas, electric components are all imported products; With fault self-diagnosis and data statistics function.

-

Portable air duct sealing machine pneumatic stainless steel plate sealing equipment steel square pipe combined with sealing gun

Pneumatic sealing machine is suitable for quick sealing of rectangular ventilation pipe, smooth appearance, strong versatility, improve the sealing quality of air pipe, reduce labor intensity, to achieve labor saving, time saving, reduce costs. This machine adopts heavy chassis, arc welding steel frame, high quality cylinder, joint wheel group after quenching and grinding processing, to ensure that the structure is strong and durable, rapid and accurate joint, with long service life.

-

Pengwo automatic CNC Angle flange production line

CNC Angle steel flange production line adopts the cooperation of CNC system and stamping machinery to complete the punching and cutting action of Angle steel, forming a complete set of flexible automatic stamping production line, stamping workers are liberated from monotonous heavy and dangerous working state, to ensure safety and improve production efficiency. CNC Angle steel flange production line system is a special system developed by our company on the basis of industrial computers of famous domestic brands. The hardware part has strong anti-seismic and anti-interference ability, the machine tool with centralized lubrication system can adapt to long time work, stable and efficient performance; Precision servo motor drive, fast speed, short response time, large torque, accurate control, ensure the feeding processing precision, good performance; Guide rail imported from Taiwan, high bearing capacity, good guidance; Adopt high precision rack imported from Taiwan, accurate and stable feeding; CNC Angle flange production line with pneumatic clamp, to prevent the Angle steel slippage in the process of driving, can fully ensure the clamping force.