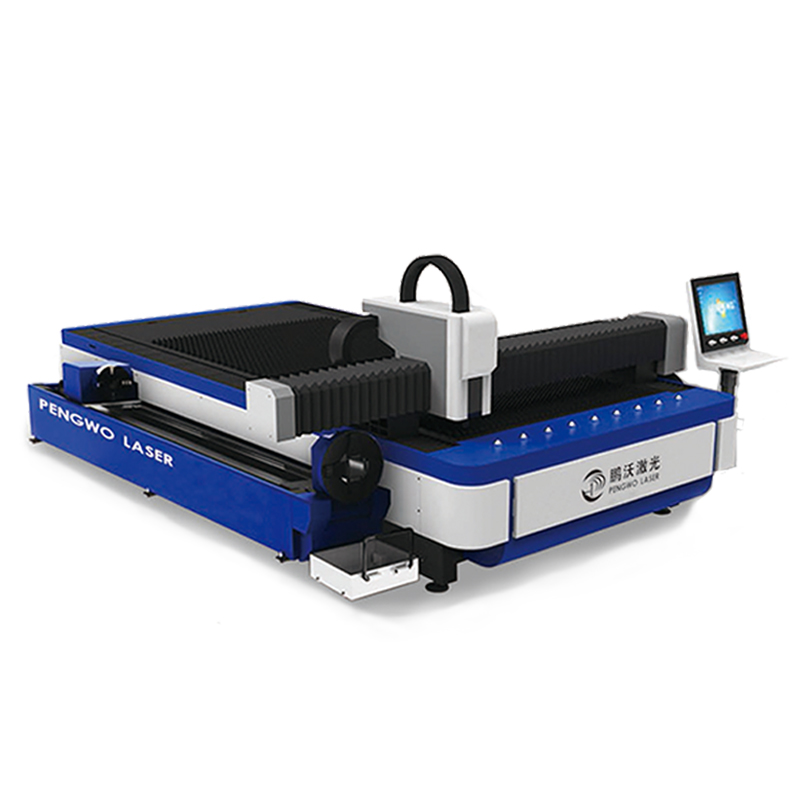

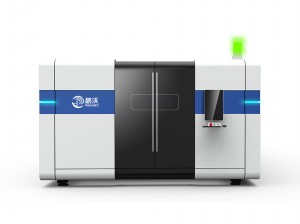

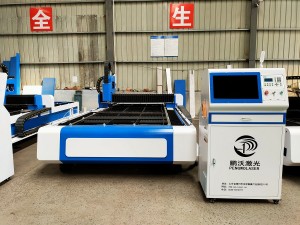

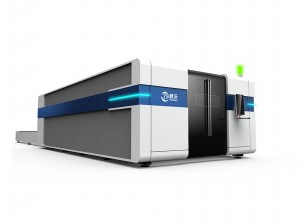

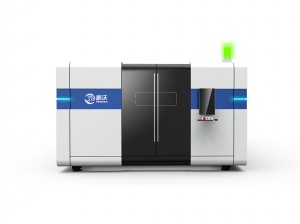

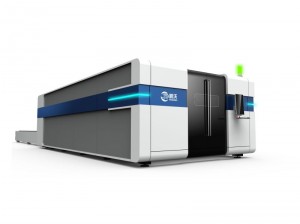

Plate and tube dual-use laser cutting machine can cut all kinds of plate and tube special-shaped tube

Application industry

Sheet metal processing, advertising sign word production, high and low voltage electrical cabinet production, mechanical parts, kitchenware, automobile, mechanical processing, saw blade, electronic parts, glasses industry, spring sheet, circuit board, electric kettle, medical electronics, hardware tools and other industries.

Applied materials

Stainless steel, carbon steel, alloy steel, spring steel, copper plate, aluminum plate, gold, silver, titanium and other metal plates

Product advantage

1. The frame adopts all-welded structure, which is firm and reasonable, easy to operate and durable.

2. Fast cutting speed and high precision. Cut small, neat, no slag phenomenon. Based on the traditional numerical control system, the cutting control mode is improved to avoid the secondary finishing.

3. Suitable for low carbon steel plate, copper plate, iron plate, aluminum plate, galvanized plate, titanium plate and other metal plate.

4. High configuration of CNC system. Automatic arc starting, stable performance, the success rate of arc starting more than 99%.

5. Support standard G code path files generated by Wentai, BeihangHaier, ARTCAM, Type3 and other software. Control system using U disk exchange processing file, easy to operate.

Specification