Company News

-

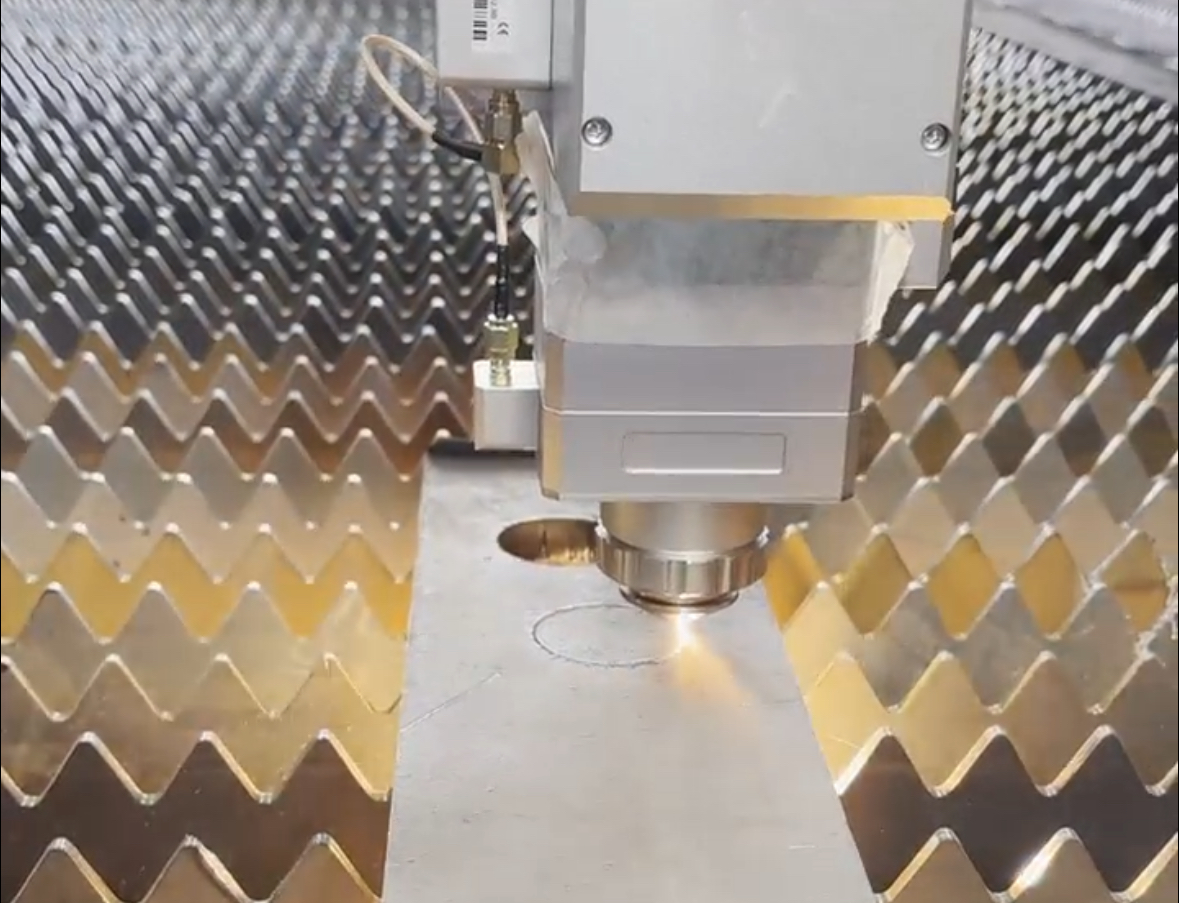

Several aspects to pay attention to in metal laser cutting

Laser cutting is the use of high energy density laser beam cutting materials of a new processing technology, the laser produced in the high energy density laser through the refraction is focused into a small beam of light spot, irradiation on the material can instantly melt the material to form a...Read more -

What are the possible problems caused by too fast laser cutting speed?

In the manufacturing industry, laser cutting machines are widely used in the cutting and processing of various materials. Cutting speed is an important parameter of laser cutting machine, which affects the processing efficiency. However, when the cutting speed is too fast, there may be a series o...Read more -

3C industry is stepping into a new era of the Internet of everything. How strong is laser + intelligent manufacturing?

What is the tuyere of 3C industry? Laser processing how to grasp tuyere, realize the break? Looking back at the technological changes in 3C industry, we are shifting from mobile Internet to the Internet of everything. 5G provides an information “highway” characterized by low-delay and...Read more -

Laser cutting machine is gradually refined to save energy

With the development of science and technology, all walks of life are also quietly changing, among them, laser cutting processing with invisible light beam instead of the traditional mechanical knife, laser cutting with high precision, cutting speed characteristics, not limited to cutting pattern...Read more -

Pengwo Laser: “Laser +” lets mobile phone manufacturing bloom the beauty of technology

Each fashionable and elegant mobile phone is full of a kind of technological beauty, and its smooth and delicate dynamic curve thin body makes people love it. Behind the gorgeous appearance of the whole phone, laser technology has contributed a lot. Because in the manufacturing process of each mo...Read more -

How to prevent summer condensation of medium/high power laser?

May Day suddenly increased the temperature, let us feel the feeling of summer. As the temperature rises, we must pay attention to the prevention of laser condensation in the high temperature and high humidity environment. When the cooling water temperature of the laser is lower than the correspon...Read more -

Pengwo Laser: “Laser +” lets mobile phone manufacturing bloom the beauty of technology

Each fashionable and elegant mobile phone is full of a kind of technological beauty, and its smooth and delicate dynamic curve thin body makes people love it. Behind the gorgeous appearance of the whole phone, laser technology has contributed a lot. Because in the manufacturing process of each mo...Read more -

The application of laser in mobile phone manufacturing

1 SIM card holder laser engraving 2 Laser engraving of mobile phone LDS antenna 3 Mobile phone card needle laser engraving 4 Laser engraving of mobile phone charger 5 Power bank laser engravingRead more -

Write Chinese culture with laser, help cultural soft power!

Panda, as a national treasure of China, has been deeply loved by people all over the world, such as the United States, Japan, France, Britain and other countries have applied to take pandas back to their home countries, among which bamboo, as the favorite food of pandas, is naturally the most pop...Read more -

What is a laser engraving machine?

What is a laser engraving machine? Laser engraving function to improve the efficiency of engraving, so that the surface of the engraving is smooth, rounded, rapidly reduce the temperature of the non-metallic materials, reduce the deformation and internal stress of the engraving; According to the...Read more -

Laser cutting stainless steel quality determination of nine standards

How to judge the quality of laser cutting? Here are nine criteria. roughness Laser cutting section will form a vertical grain, grain depth determines the roughness of the cutting surface, the shallower the grain, the smoother the cutting section. Roughness not only affects the appearance of the e...Read more -

What are the advantages of plasma cleaners?

plasma cleaner (plasma cleaner), also known as plasma cleaner, or plasma surface treatment instrument, is a new high-tech technology, the use of plasma to achieve the effect of conventional cleaning methods can not be achieved. Plasma is a state of matter, also known as the fourth state of matter...Read more