Plasma cutting equipment series

-

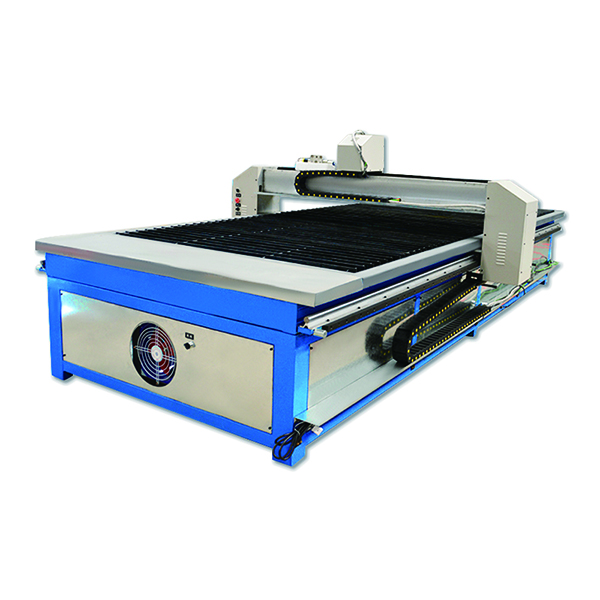

Metal processing industry 1530 most favorable price CNC plasma cutting machine plasma cutting machine

1. The frame adopts the whole welded structure, strong and reasonable, simple operation, durable

2. Fast cutting speed, high precision, small cutting mouth, neat, no slag phenomenon On the basis of the traditional numerical control system, improved the cutting control mode,

to avoid the secondary dressing processing

3. Suitable for low carbon steel plate, copper plate, iron plate, aluminum plate, galvanized plate, titanium plate and other metal plates

4. CNC system configuration of high automatic arc starting, stable performance, arc starting success rate of more than 99

5. Support a variety of software generated standard G code path file control system using U disk exchange processing files, easy to operate -

Manufacturers supply plasma cutting machines

Plasma cutting is a kind of processing method that uses the heat of high temperature plasma arc to melt (and evaporate) the metal part or part of the workpiece incision, and uses the momentum of high speed plasma to remove the molten metal to form the incision.

Features 1. Automatic and semi-automatic cutting double mode selection

2. Digital precise control of cutting length 3. Easy to operate

-

Plasma cutting machine

Plasma cutting is a kind of processing method that uses the heat of high temperature plasma arc to melt (and evaporate) the metal part or part of the workpiece incision, and uses the momentum of high speed plasma to remove the molten metal to form the incision.

Features 1. Automatic and semi-automatic cutting double mode selection

2. Digital precise control of cutting length 3. Easy to operate

-

Plasma cutting

Plasma cutting is a kind of processing method that uses the heat of high temperature plasma arc to melt (and evaporate) the metal part or part of the workpiece incision, and uses the momentum of high speed plasma to remove the molten metal to form the incision.

Features 1. Automatic and semi-automatic cutting double mode selection

2. Digital precise control of cutting length 3. Easy to operate

-

Plate and tube dual-use laser cutting machine can cut all kinds of plate and tube special-shaped tube

Plasma cutting is a kind of processing method that uses the heat of high temperature plasma arc to melt (and evaporate) the metal part or part of the workpiece incision, and uses the momentum of high speed plasma to remove the molten metal to form the incision.

Features 1. Automatic and semi-automatic cutting double mode selection

2. Digital precise control of cutting length 3. Easy to operate

-

Plasma cutting machine

Plasma cutting is a kind of processing method that uses the heat of high temperature plasma arc to melt (and evaporate) the metal part or part of the workpiece incision, and uses the momentum of high speed plasma to remove the molten metal to form the incision.

Features 1. Automatic and semi-automatic cutting double mode selection

2. Digital precise control of cutting length 3. Easy to operate

-

Manufacturers supply plasma cutting machines

1: high precision

2: good cutting quality: the cutting edge is affected by heat very little, basically no workpiece thermal deformation, completely avoid the material punching shear formed when the edge, slit generally do not need two processing

3: not affected by the hardness of the cut material: can be processed on steel plate stainless steel aluminum alloy plate carbide, no matter what kind of hardness, can be cut without deformation

4: Plasma cutting machine is widely used in automobile locomotive pressure vessel chemical machinery nuclear industry general machinery engineering machinery steel structure and other industries

-

Manufacturers supply high power plasma cutting machines

Plasma cutting is a kind of processing method that uses the heat of high temperature plasma arc to melt (and evaporate) the metal part or part of the workpiece incision, and uses the momentum of high speed plasma to remove the molten metal to form the incision.

Features 1. Automatic and semi-automatic cutting double mode selection

2. Digital precise control of cutting length 3. Easy to operate

-

Full automatic metal plate table flame cutting machine gantry type CNC flame plasma dual-use cutting machine

1: high precision

2: good cutting quality: the cutting edge is affected by heat very little, basically no workpiece thermal deformation, completely avoid the material punching shear formed when the edge, slit generally do not need two processing

3: not affected by the hardness of the cut material: can be processed on steel plate stainless steel aluminum alloy plate carbide, no matter what kind of hardness, can be cut without deformation

4: Plasma cutting machine is widely used in automobile locomotive pressure vessel chemical machinery nuclear industry general machinery engineering machinery steel structure and other industries

-

Plate and tube dual-use laser cutting machine can cut all kinds of plate and tube special-shaped tube

Plasma cutting is a kind of processing method that uses the heat of high temperature plasma arc to melt (and evaporate) the metal part or part of the workpiece incision, and uses the momentum of high speed plasma to remove the molten metal to form the incision.

Features 1. Automatic and semi-automatic cutting double mode selection

2. Digital precise control of cutting length 3. Easy to operate

-

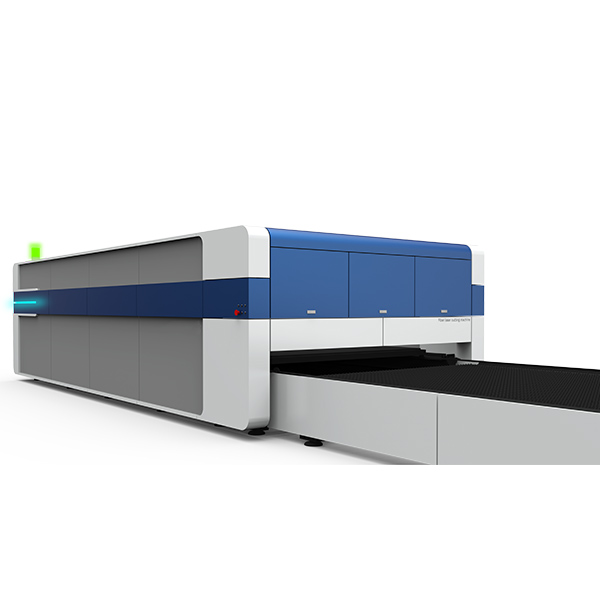

Closed switched 2040 fiber laser cutting machine

Enclosed design, in line with European CE standards,Configure the switching workbench,Loading and unloading is convenient and quick,Further improve production efficiency,For high speed motion requirements,Design and manufacture reinforced welded type beds,Two effective treatment, to ensure the bed long – term operation of the accuracy and stability.Standard metal professional automatic typesetting software (including material management, processing technology optimization and other functions),Provide process parameter library, so that the operator more simple,Optimized optics, specially designed nozzles and sensor technology make cutting smoother and more stable,The 1500x4000mm 2000mm x4000mm 2000mm x6000mm 2500x6000mm workbench is optional,Application industry: Mechanical and electrical equipment sheet metal processing chassis cabinet stainless steel products kitchen lighting accessories automobile accessories glasses hardware tools advertising sign decoration and many other industries.Processing materials: stainless steel (including pipe) carbon steel (including pipe) stainless iron (including pipe) galvanized iron plate aluminum alloy (including pipe) aluminum copper rare metal plate

-

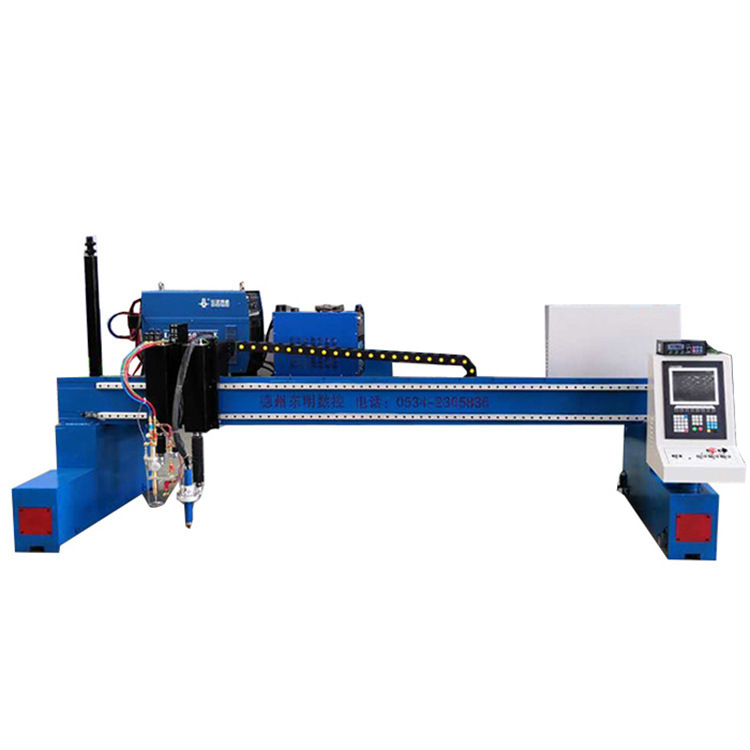

Manufacturer supply dragon gate flame cutting machine flame plasma cutting machine plasma cutting machine can be customized

Gantry type structure, the transverse span is 2m-10m and other specifications, all using double axis guide rail, bilateral drive, according to user requirements can be configured with more flame, plasma cutting torch and matching automatic height system, can be configured into CNC cutting and straight cutting, as well as the use of intersecting line. The two sides are respectively driven by pinion and rack, industrial modeling structure, advanced humanized industrial control technology, configuration of plasma system, transmission system, control system mainly for medium and thick plate cutting.

Gantry type CNC plasma cutting machine main features: Adopting soft switch inverter technology, cutting current stability, high load sustained rate, suitable for heavy industry, cutting current slow rise technology, reduce cutting gun accessories consumption, with wide power grid voltage adaptability, unique dust-proof design, high reliability of the whole machine, compact structure, small size, light weight, can be installed on CNC machine cutting air source with cheap compressed air, Low cutting cost preset cutting current, stepless adjustable, with plasma gas pressure detection, indicating function, with test qi work, easy to adjust the air pressure, with overheating, overpressure, underpressure, phase automatic protection function