Intersecting line plasma cutter

-

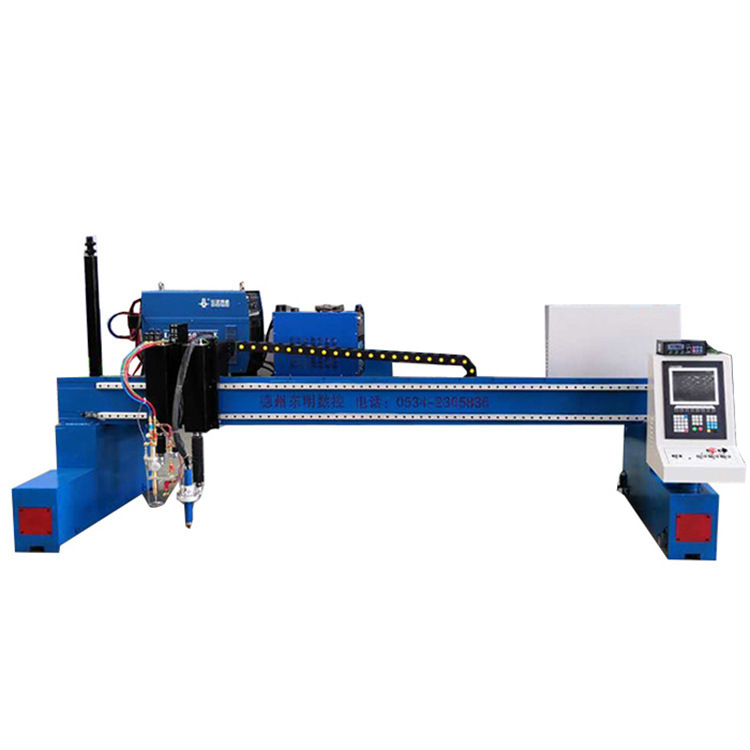

Manufacturers supply gantry type plasma cutting machine can be customized plasma cutting machine

Gantry type structure, the transverse span is 2m-10m and other specifications, all using double axis guide rail, bilateral drive, according to user requirements can be configured with more flame, plasma cutting torch and matching automatic height system, can be configured into CNC cutting and straight cutting, as well as the use of intersecting line. The two sides are respectively driven by pinion and rack, industrial modeling structure, advanced humanized industrial control technology, configuration of plasma system, transmission system, control system mainly for medium and thick plate cutting.

Gantry type CNC plasma cutting machine main features: Adopting soft switch inverter technology, cutting current stability, high load sustained rate, suitable for heavy industry, cutting current slow rise technology, reduce cutting gun accessories consumption, with wide power grid voltage adaptability, unique dust-proof design, high reliability of the whole machine, compact structure, small size, light weight, can be installed on CNC machine cutting air source with cheap compressed air, Low cutting cost preset cutting current, stepless adjustable, with plasma gas pressure detection, indicating function, with test qi work, easy to adjust the air pressure, with overheating, overpressure, underpressure, phase automatic protection function

-

Five axis intersecting line cutting machine round tube five axis four linkage NC intersecting line cutting plasma cutting machine

1 is the accuracy, the traditional artificial hand-held plasma and flame cutting of various phases of the mouth, the longer the working time of the accuracy of the gap is also very much, there is a little attention will produce a great error our intersecting line cutting machine using Japanese Panasonic servo motor control operation, cutting operation precision

2. Cutting efficiency Manual cutting speed is slow, some places the error is larger or need to carry out secondary processing, production efficiency will be greatly reduced, each cutting also requires the size of the crossing line cutting machine directly with CAD to make cutting graphics, directly generate cutting code, do not need manual marking, direct cutting export type

3. When receiving a very large project, the transportation cost is also very large. The intersecting line cutting machine of our company adopts the process of the whole chassis, which is divided into 2-3 sections for convenient transportation Direct use

4. There is a fatigue period, many factors will lead to a decline in production efficiency, but the intersecting line cutting machine does not, as long as the cutting conditions can work 1-2 people can complete the operation, only the feeding level, the operation of the industrial control computer, the cutting workpiece can be picked up and finished -

Manufacturer supply dragon gate flame cutting machine flame plasma cutting machine plasma cutting machine can be customized

Gantry type structure, the transverse span is 2m-10m and other specifications, all using double axis guide rail, bilateral drive, according to user requirements can be configured with more flame, plasma cutting torch and matching automatic height system, can be configured into CNC cutting and straight cutting, as well as the use of intersecting line. The two sides are respectively driven by pinion and rack, industrial modeling structure, advanced humanized industrial control technology, configuration of plasma system, transmission system, control system mainly for medium and thick plate cutting.

Gantry type CNC plasma cutting machine main features: Adopting soft switch inverter technology, cutting current stability, high load sustained rate, suitable for heavy industry, cutting current slow rise technology, reduce cutting gun accessories consumption, with wide power grid voltage adaptability, unique dust-proof design, high reliability of the whole machine, compact structure, small size, light weight, can be installed on CNC machine cutting air source with cheap compressed air, Low cutting cost preset cutting current, stepless adjustable, with plasma gas pressure detection, indicating function, with test qi work, easy to adjust the air pressure, with overheating, overpressure, underpressure, phase automatic protection function

-

Intersecting line cutter

1 is the accuracy, the traditional artificial hand-held plasma and flame cutting of various phases of the mouth, the longer the working time of the accuracy of the gap is also very much, there is a little attention will produce a great error our intersecting line cutting machine using Japanese Panasonic servo motor control operation, cutting operation precision

2. Cutting efficiency Manual cutting speed is slow, some places the error is larger or need to carry out secondary processing, production efficiency will be greatly reduced, each cutting also requires the size of the crossing line cutting machine directly with CAD to make cutting graphics, directly generate cutting code, do not need manual marking, direct cutting export type

3. When receiving a very large project, the transportation cost is also very large. The intersecting line cutting machine of our company adopts the process of the whole chassis, which is divided into 2-3 sections for convenient transportation Direct use

4. There is a fatigue period, many factors will lead to a decline in production efficiency, but the intersecting line cutting machine does not, as long as the cutting conditions can work 1-2 people can complete the operation, only the feeding level, the operation of the industrial control computer, the cutting workpiece can be picked up and finished -

KR-XY5 five axis cylindrical tube intersecting line cutting

1 is the accuracy, the traditional artificial hand-held plasma and flame cutting of various phases of the mouth, the longer the working time of the accuracy of the gap is also very much, there is a little attention will produce a great error our intersecting line cutting machine using Japanese Panasonic servo motor control operation, cutting operation precision

2. Cutting efficiency Manual cutting speed is slow, some places the error is larger or need to carry out secondary processing, production efficiency will be greatly reduced, each cutting also requires the size of the crossing line cutting machine directly with CAD to make cutting graphics, directly generate cutting code, do not need manual marking, direct cutting export type

3. When receiving a very large project, the transportation cost is also very large. The intersecting line cutting machine of our company adopts the process of the whole chassis, which is divided into 2-3 sections for convenient transportation Direct use

4. There is a fatigue period, many factors will lead to a decline in production efficiency, but the intersecting line cutting machine does not, as long as the cutting conditions can work 1-2 people can complete the operation, only the feeding level, the operation of the industrial control computer, the cutting workpiece can be picked up and finished -

Plasma intersecting line cutter

1 is the accuracy, the traditional artificial hand-held plasma and flame cutting of various phases of the mouth, the longer the working time of the accuracy of the gap is also very much, there is a little attention will produce a great error our intersecting line cutting machine using Japanese Panasonic servo motor control operation, cutting operation precision

2. Cutting efficiency Manual cutting speed is slow, some places the error is larger or need to carry out secondary processing, production efficiency will be greatly reduced, each cutting also requires the size of the crossing line cutting machine directly with CAD to make cutting graphics, directly generate cutting code, do not need manual marking, direct cutting export type

3. When receiving a very large project, the transportation cost is also very large. The intersecting line cutting machine of our company adopts the process of the whole chassis, which is divided into 2-3 sections for convenient transportation Direct use

4. There is a fatigue period, many factors will lead to a decline in production efficiency, but the intersecting line cutting machine does not, as long as the cutting conditions can work 1-2 people can complete the operation, only the feeding level, the operation of the industrial control computer, the cutting workpiece can be picked up and finished