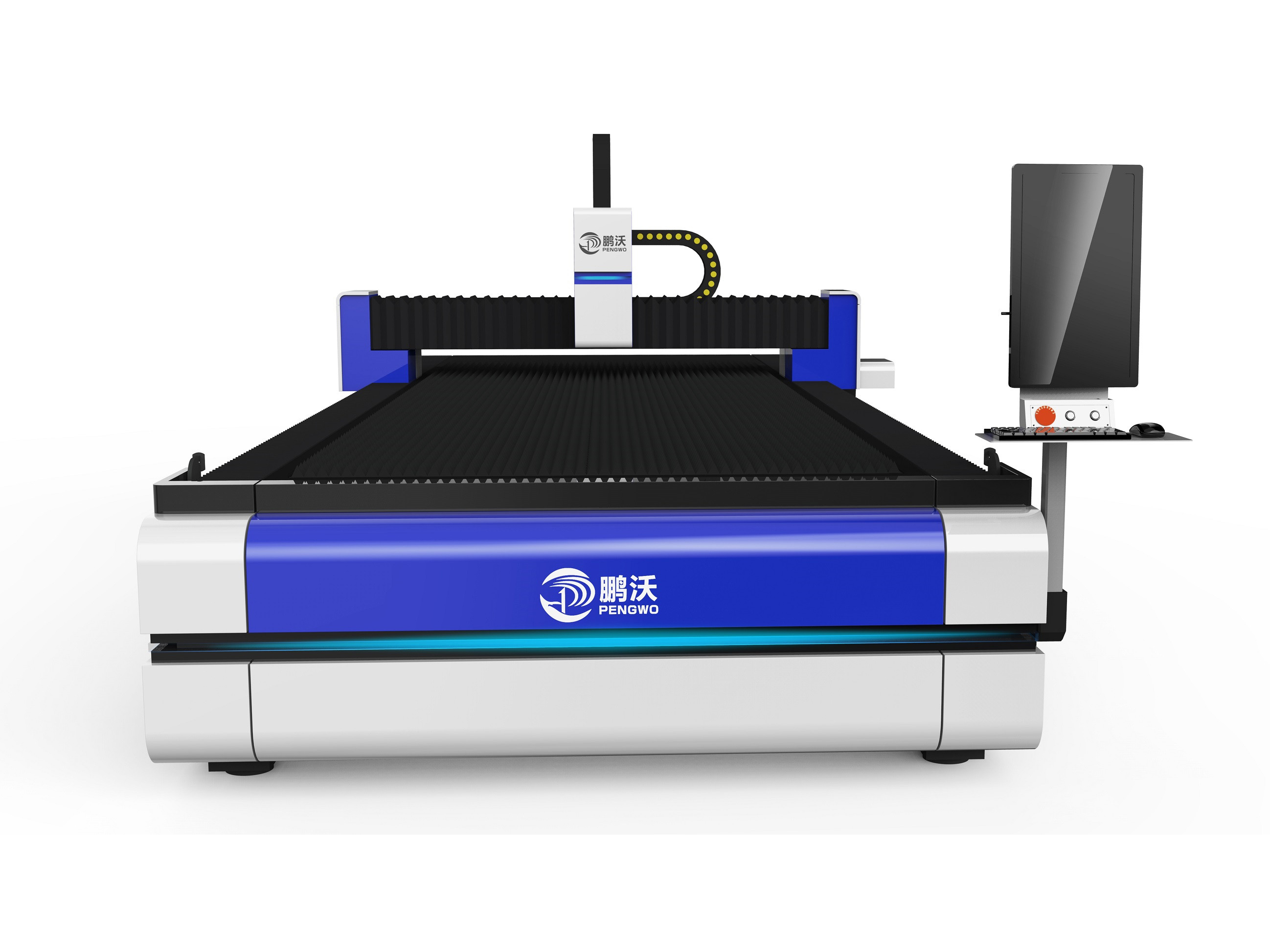

Open laser cutting machine

-

3000*1500mm CNC Laser Cutting Machine Fiber Laser Cutter Stainless Steel Sheet Tube Cutting With 1000W 2000W Laser Source

Excellent beam quality: smaller focusing spot, finer cutting lines, higher work efficiency, better processing quality; High cutting speed: is the same power CO, laser cutting machine 2 times; Extremely high stability: the world’s top imported fiber laser, stable performance, the service life of key components can reach 100,000 hours; Extremely high electro-optical conversion efficiency: optical fiber laser cutting machine photoelectric conversion efficiency of about 30%, is C0, laser cutting machine 3 times higher, energy saving and environmental protection; The power consumption of the whole machine is only 20-30% of the similar C0 laser cutting machine; Super flexible light guide effect: compact size, compact structure, easy to flexible processing requirements.The double ball screw closed-loop system and open CNC system enable high processing accuracy and high working efficiency during high speed cutting,while the man-machine interface is friendly.Can be equipped with different power of fiber laser: 500W/700W/1000W/1500W,etc.,operation and maintenance cost is low.Standard collocation of dual-pressuregascontrol system of 3 gas source (high pressure air, nitrogen and oxygen) meets the customer demand for a variety of materials processing, simple operation and lower cost.The software supports the input and output of general CAD (PLT, DXF, DST, AI, BMP, etc.) format file.

-

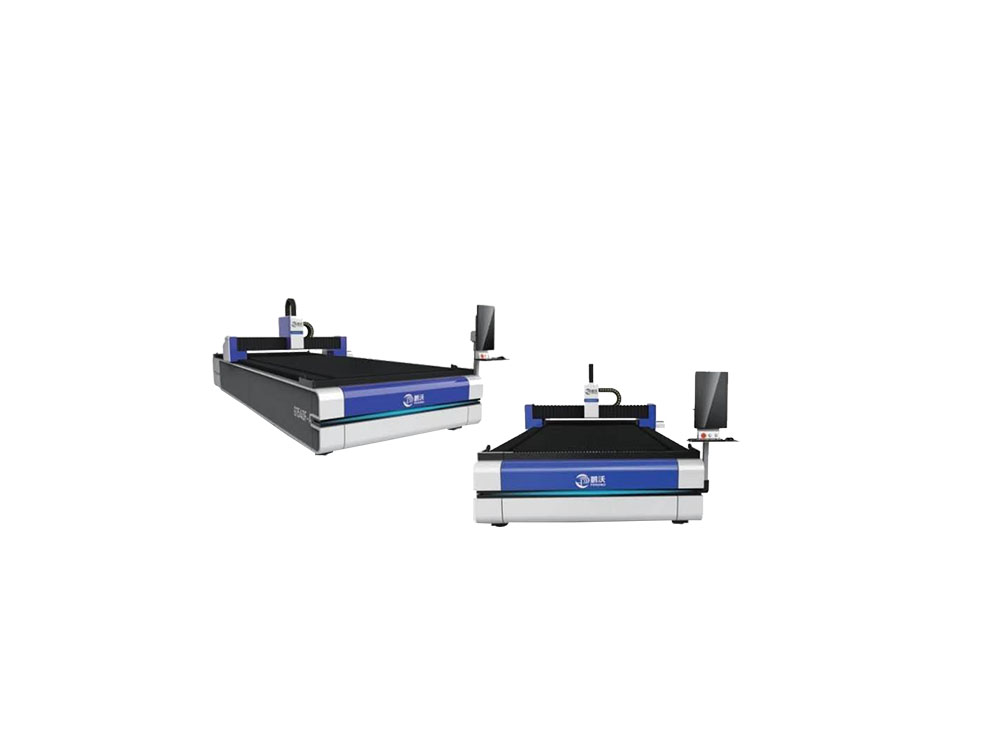

best price Raycus IPG 3015 1000w 1500w 2000w 3000w 6000w cnc metal metal fiber laser cutting machine

1.Equipped with raw material trays and finished material trays, which can realize automatic transfer back to the warehouse and meet the needs of small, medium, large, and varieties of plates.

* 2.Both the collimating lens and the focusing lens group are cooling accessories. Besides, the cooling airflow nozzle is added, which effectively protects the nozzle and the ceramics and prolongs the working time.

* 3.Without human interference, the focusing speed can reach 10m/min, and the repeatability is about 50 microns.

* 4.Adopting high-quality carbon steel welding bed, it has strong structural rigidity, small deformation, and low vibration toensure cutting accuracy. -

Oreelaser metal laser cutter CNC fiber laser cutting machine sheet metal

Machine Features:

1. High-performance laser device associated with stable operation system enables optimal cutting effects.

2. Perfect cooling, lubrication and dedusting systems ensure stable, efficient and durable performance of the whole machine.

3. Single countertop make plates loading and unloading available during cutting, which improves the processing eficiency.

4. Large-size closed enclosure improves dedusting effects and avoids optical pollution.

5. Automatic height-adjustment performance keeps constant focal length and stable cutting quality.

6. Gantry structure and inblock aluminum cast cross beam make the device highly rigid, stable and antiknock.

7. It could ut mental in various materials and realize excellent and stable cutting effects. -

Manufacturers supply 6000w open laser cutting machine

Excellent beam quality: smaller focusing spot, finer cutting lines, higher working efficiency, better processing quality; High cutting speed: is the same power CO, laser cutting machine 2 times; High stability: the world’s top imported fiber laser, stable performance, the service life of key components can reach 100,000 hours; High electro-optic conversion efficiency: optical fiber laser cutting machine photoelectric conversion efficiency of about 30%, is C0, laser cutting machine 3 times higher, energy saving and environmental protection; The power consumption of the whole machine is only 20-30% of that of the similar C0 laser cutting machine. Super flexible light guide effect: small size, compact structure, easy to flexible processing requirements.

-

3000w open laser cutting machine

Excellent beam quality: smaller focusing spot, finer cutting lines, higher work efficiency, better processing quality; High cutting speed: is the same power CO, laser cutting machine 2 times; Extremely high stability: the world’s top imported fiber laser, stable performance, the service life of key components can reach 100,000 hours; Extremely high electro-optical conversion efficiency: optical fiber laser cutting machine photoelectric conversion efficiency of about 30%, is C0, laser cutting machine 3 times higher, energy saving and environmental protection; The power consumption of the whole machine is only 20-30% of the similar C0 laser cutting machine; Super flexible light guide effect: compact size, compact structure, easy to flexible processing requirements.The double ball screw closed-loop system and open CNC system enable high processing accuracy and high working efficiency during high speed cutting,while the man-machine interface is friendly.Can be equipped with different power of fiber laser: 500W/700W/1000W/1500W,etc.,operation and maintenance cost is low.Standard collocation of dual-pressuregascontrol system of 3 gas source (high pressure air, nitrogen and oxygen) meets the customer demand for a variety of materials processing, simple operation and lower cost.The software supports the input and output of general CAD (PLT, DXF, DST, AI, BMP, etc.) format file.

-

4000Wopen laser cutting machine

Excellent beam quality: smaller focusing spot, finer cutting lines, higher work efficiency, better processing quality; High cutting speed: is the same power CO, laser cutting machine 2 times; Extremely high stability: the world’s top imported fiber laser, stable performance, the service life of key components can reach 100,000 hours; Extremely high electro-optical conversion efficiency: optical fiber laser cutting machine photoelectric conversion efficiency of about 30%, is C0, laser cutting machine 3 times higher, energy saving and environmental protection; The power consumption of the whole machine is only 20-30% of the similar C0 laser cutting machine; Super flexible light guide effect: compact size, compact structure, easy to flexible processing requirements.The double ball screw closed-loop system and open CNC system enable high processing accuracy and high working efficiency during high speed cutting,while the man-machine interface is friendly.Can be equipped with different power of fiber laser: 500W/700W/1000W/1500W,etc.,operation and maintenance cost is low.Standard collocation of dual-pressuregascontrol system of 3 gas source (high pressure air, nitrogen and oxygen) meets the customer demand for a variety of materials processing, simple operation and lower cost.The software supports the input and output of general CAD (PLT, DXF, DST, AI, BMP, etc.) format file.

-

Manufacturers supply 2560 open fiber laser cutting machine

Excellent beam quality: smaller focusing spot, finer cutting lines, higher work efficiency, better processing quality; High cutting speed: is the same power CO, laser cutting machine 2 times; Extremely high stability: the world’s top imported fiber laser, stable performance, the service life of key components can reach 100,000 hours; Extremely high electro-optical conversion efficiency: optical fiber laser cutting machine photoelectric conversion efficiency of about 30%, is C0, laser cutting machine 3 times higher, energy saving and environmental protection; The power consumption of the whole machine is only 20-30% of the similar C0 laser cutting machine; Super flexible light guide effect: compact size, compact structure, easy to flexible processing requirements.The double ball screw closed-loop system and open CNC system enable high processing accuracy and high working efficiency during high speed cutting,while the man-machine interface is friendly.Can be equipped with different power of fiber laser: 500W/700W/1000W/1500W,etc.,operation and maintenance cost is low.Standard collocation of dual-pressuregascontrol system of 3 gas source (high pressure air, nitrogen and oxygen) meets the customer demand for a variety of materials processing, simple operation and lower cost.The software supports the input and output of general CAD (PLT, DXF, DST, AI, BMP, etc.) format file.

-

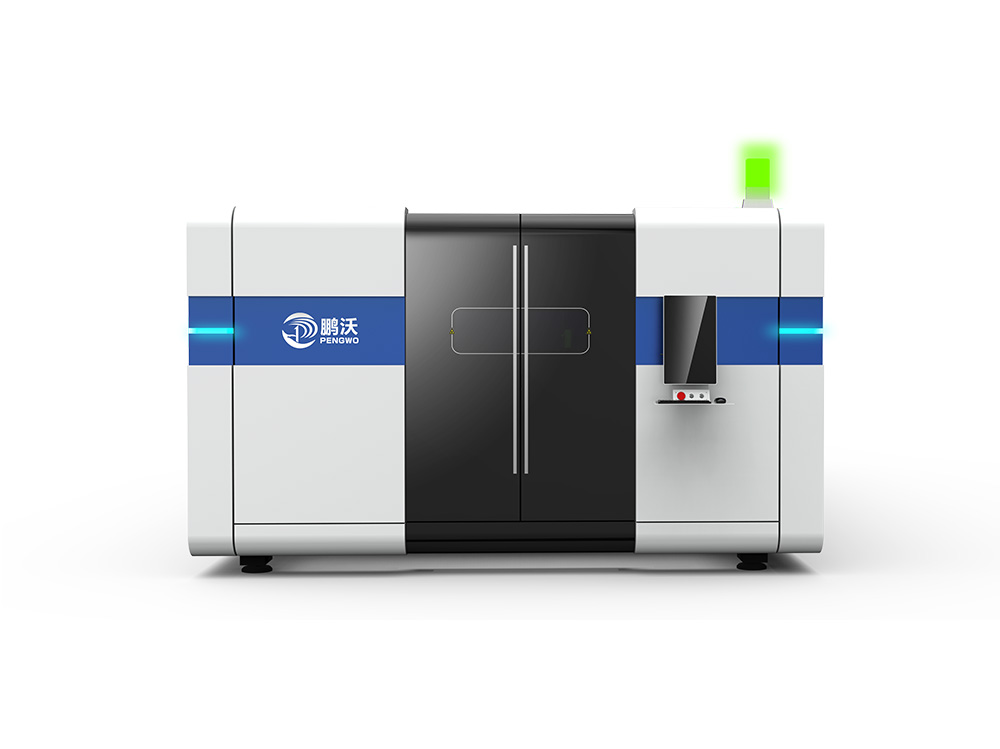

Manufacturer supply high power 2060 closed switched fiber laser cutting machine

2000W fiber laser is standard, 1000W-3000W fiber laser is optional, low operation and maintenance cost. Encircle design, in line with European CE standard, safe and reliable processing, configuration of exchange table, loading and unloading convenient, further improve production efficiency. According to the requirements of high speed movement, design and manufacture of reinforced welded bed, two effective treatment, to ensure the long-term operation of the bed precision and stability.Standard equipped with three air sources and double pressure air control system (high-pressure air, nitrogen, oxygen), to meet customers’ requirements for processing various materials, simple operation, lower cost. Standard metal professional automatic typesetting software (including material management, process optimization and other functions), provide process parameters library, so that the operator is simpler, easier to manage.Optimized optics, specially designed nozzles and sensor technology make cutting smoother and more stable. 2000mm x 4000mm and 2000mm x 6000mm worktables are available.