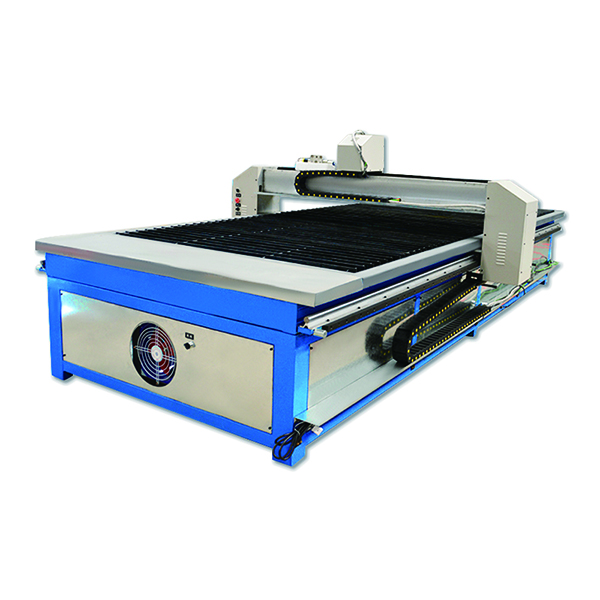

Plasma bench cutting machine

-

Metal processing industry 1530 most favorable price CNC plasma cutting machine plasma cutting machine

1. The frame adopts the whole welded structure, strong and reasonable, simple operation, durable

2. Fast cutting speed, high precision, small cutting mouth, neat, no slag phenomenon On the basis of the traditional numerical control system, improved the cutting control mode,

to avoid the secondary dressing processing

3. Suitable for low carbon steel plate, copper plate, iron plate, aluminum plate, galvanized plate, titanium plate and other metal plates

4. CNC system configuration of high automatic arc starting, stable performance, arc starting success rate of more than 99

5. Support a variety of software generated standard G code path file control system using U disk exchange processing files, easy to operate -

Plasma cutting

Plasma cutting is a kind of processing method that uses the heat of high temperature plasma arc to melt (and evaporate) the metal part or part of the workpiece incision, and uses the momentum of high speed plasma to remove the molten metal to form the incision.

Features 1. Automatic and semi-automatic cutting double mode selection

2. Digital precise control of cutting length 3. Easy to operate

-

Full automatic metal plate table flame cutting machine gantry type CNC flame plasma dual-use cutting machine

1: high precision

2: good cutting quality: the cutting edge is affected by heat very little, basically no workpiece thermal deformation, completely avoid the material punching shear formed when the edge, slit generally do not need two processing

3: not affected by the hardness of the cut material: can be processed on steel plate stainless steel aluminum alloy plate carbide, no matter what kind of hardness, can be cut without deformation

4: Plasma cutting machine is widely used in automobile locomotive pressure vessel chemical machinery nuclear industry general machinery engineering machinery steel structure and other industries

-

Plasma cutting machine

Plasma cutting is a kind of processing method that uses the heat of high temperature plasma arc to melt (and evaporate) the metal part or part of the workpiece incision, and uses the momentum of high speed plasma to remove the molten metal to form the incision.

Features 1. Automatic and semi-automatic cutting double mode selection

2. Digital precise control of cutting length 3. Easy to operate

-

Plate and tube dual-use laser cutting machine can cut all kinds of plate and tube special-shaped tube

Plasma cutting is a kind of processing method that uses the heat of high temperature plasma arc to melt (and evaporate) the metal part or part of the workpiece incision, and uses the momentum of high speed plasma to remove the molten metal to form the incision.

Features 1. Automatic and semi-automatic cutting double mode selection

2. Digital precise control of cutting length 3. Easy to operate

-

Plasma cutting machine

Plasma cutting is a kind of processing method that uses the heat of high temperature plasma arc to melt (and evaporate) the metal part or part of the workpiece incision, and uses the momentum of high speed plasma to remove the molten metal to form the incision.

Features 1. Automatic and semi-automatic cutting double mode selection

2. Digital precise control of cutting length 3. Easy to operate

-

Manufacturers supply plasma cutting machines

1: high precision

2: good cutting quality: the cutting edge is affected by heat very little, basically no workpiece thermal deformation, completely avoid the material punching shear formed when the edge, slit generally do not need two processing

3: not affected by the hardness of the cut material: can be processed on steel plate stainless steel aluminum alloy plate carbide, no matter what kind of hardness, can be cut without deformation

4: Plasma cutting machine is widely used in automobile locomotive pressure vessel chemical machinery nuclear industry general machinery engineering machinery steel structure and other industries

-

Manufacturers supply high power plasma cutting machines

Plasma cutting is a kind of processing method that uses the heat of high temperature plasma arc to melt (and evaporate) the metal part or part of the workpiece incision, and uses the momentum of high speed plasma to remove the molten metal to form the incision.

Features 1. Automatic and semi-automatic cutting double mode selection

2. Digital precise control of cutting length 3. Easy to operate

-

Plate and tube dual-use laser cutting machine can cut all kinds of plate and tube special-shaped tube

Plasma cutting is a kind of processing method that uses the heat of high temperature plasma arc to melt (and evaporate) the metal part or part of the workpiece incision, and uses the momentum of high speed plasma to remove the molten metal to form the incision.

Features 1. Automatic and semi-automatic cutting double mode selection

2. Digital precise control of cutting length 3. Easy to operate

-

Manufacturers supply plasma cutting machines

Plasma cutting is a kind of processing method that uses the heat of high temperature plasma arc to melt (and evaporate) the metal part or part of the workpiece incision, and uses the momentum of high speed plasma to remove the molten metal to form the incision.

Features 1. Automatic and semi-automatic cutting double mode selection

2. Digital precise control of cutting length 3. Easy to operate