Cutting – welding – rust removal three-in-one machine

-

3000*1500mm CNC Laser Cutting Machine Fiber Laser Cutter Stainless Steel Sheet Tube Cutting With 1000W 2000W Laser Source

Excellent beam quality: smaller focusing spot, finer cutting lines, higher work efficiency, better processing quality; High cutting speed: is the same power CO, laser cutting machine 2 times; Extremely high stability: the world’s top imported fiber laser, stable performance, the service life of key components can reach 100,000 hours; Extremely high electro-optical conversion efficiency: optical fiber laser cutting machine photoelectric conversion efficiency of about 30%, is C0, laser cutting machine 3 times higher, energy saving and environmental protection; The power consumption of the whole machine is only 20-30% of the similar C0 laser cutting machine; Super flexible light guide effect: compact size, compact structure, easy to flexible processing requirements.The double ball screw closed-loop system and open CNC system enable high processing accuracy and high working efficiency during high speed cutting,while the man-machine interface is friendly.Can be equipped with different power of fiber laser: 500W/700W/1000W/1500W,etc.,operation and maintenance cost is low.Standard collocation of dual-pressuregascontrol system of 3 gas source (high pressure air, nitrogen and oxygen) meets the customer demand for a variety of materials processing, simple operation and lower cost.The software supports the input and output of general CAD (PLT, DXF, DST, AI, BMP, etc.) format file.

-

best price Raycus IPG 3015 1000w 1500w 2000w 3000w 6000w cnc metal metal fiber laser cutting machine

1.Equipped with raw material trays and finished material trays, which can realize automatic transfer back to the warehouse and meet the needs of small, medium, large, and varieties of plates.

* 2.Both the collimating lens and the focusing lens group are cooling accessories. Besides, the cooling airflow nozzle is added, which effectively protects the nozzle and the ceramics and prolongs the working time.

* 3.Without human interference, the focusing speed can reach 10m/min, and the repeatability is about 50 microns.

* 4.Adopting high-quality carbon steel welding bed, it has strong structural rigidity, small deformation, and low vibration toensure cutting accuracy. -

Oreelaser metal laser cutter CNC fiber laser cutting machine sheet metal

Machine Features:

1. High-performance laser device associated with stable operation system enables optimal cutting effects.

2. Perfect cooling, lubrication and dedusting systems ensure stable, efficient and durable performance of the whole machine.

3. Single countertop make plates loading and unloading available during cutting, which improves the processing eficiency.

4. Large-size closed enclosure improves dedusting effects and avoids optical pollution.

5. Automatic height-adjustment performance keeps constant focal length and stable cutting quality.

6. Gantry structure and inblock aluminum cast cross beam make the device highly rigid, stable and antiknock.

7. It could ut mental in various materials and realize excellent and stable cutting effects. -

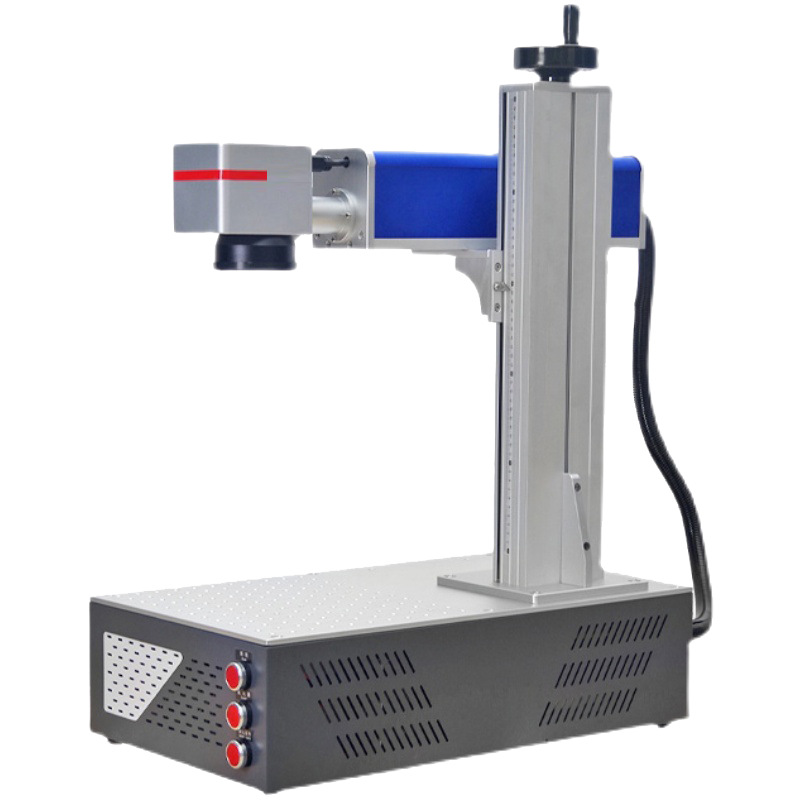

Factory direct laser marking machine 20W metal plastic stainless steel brass

Fiber laser marking machine is the use of laser beam on a variety of different substances on the surface of the permanent mark. Marking effect is through the evaporation of the surface material to reveal the deep material, or through the chemical and physical changes of the surface material caused by light energy to “carve” traces, or through the light energy to burn part of the material, showing the pattern, text, bar code and other graphics that need to be etched. The so-called fiber laser marking machine refers to the marking machine is the use of fiber laser, fiber laser has a small size (no water cooling device, the use of air cooling), good beam quality (fundamental mode), maintenance free and other characteristics.

-

Metal processing industry 1530 most favorable price CNC plasma cutting machine plasma cutting machine

1. The frame adopts the whole welded structure, strong and reasonable, simple operation, durable

2. Fast cutting speed, high precision, small cutting mouth, neat, no slag phenomenon On the basis of the traditional numerical control system, improved the cutting control mode,

to avoid the secondary dressing processing

3. Suitable for low carbon steel plate, copper plate, iron plate, aluminum plate, galvanized plate, titanium plate and other metal plates

4. CNC system configuration of high automatic arc starting, stable performance, arc starting success rate of more than 99

5. Support a variety of software generated standard G code path file control system using U disk exchange processing files, easy to operate -

W11-12×3000 symmetrical up-regulating three-roll plate coiler

This machine is an automatic two-axis plate winding machine, mainly used in the operation process of bending, at room temperature, the plate winding machine can be rolled into a cylindrical shape, punching plate round – hole round – section arc.

The upper roll is lifted and pressed by the motor through the reducer, transmission shaft, worm gear and worm pair, screw nut pair to transfer power, resulting in bending deformation of the steel plate. Coil drive through the main motor through the main reducer, open gear drive roller rotation, and become the driving roller when rolling plate. Because the lower roller elevation is unchanged, it is easy to feed and operate. Is a very general equipment, is the boiler, shipbuilding, petrochemical, cement, electric machine manufacturing of the main key equipment. The equipment has the advantages of simple structure, compact, convenient operation and high efficiency. The product roundness deviation is less than 0.5mm, the lower roll of the winding machine adopts hydraulic cylinder, which can not only ensure the smooth movement process, but also stable pressure during the rolling process, so as to ensure that the distance between the lower roll and the upper roll is constant. In the whole product forming process, the material deformation degree of each smiling distance is less than 0.5mm

-

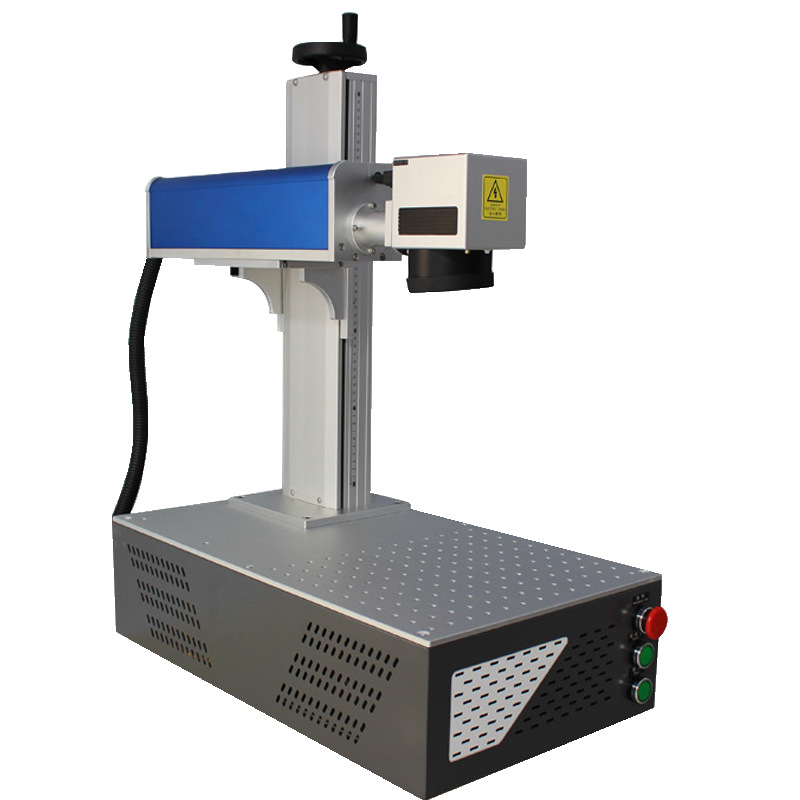

Desktop optical fiber marking machine

The working principle of the laser coding machine is to gather the laser at a very high energy density on the surface of the object to be engraved. By burning and etching, the material on the surface is vaporized, and the effective displacement of the laser beam is controlled.

According to the different marking forms, laser marking equipment can be divided into two types: marking type and dot matrix type. At present, most laser coding equipment in the market is marked, but Markon’s laser coding equipment is using a new lattice technology – lattice resident technology. Marking laser machine is mainly to mark the character of the track completely scratched out, and dot-matrix laser machine is to mark the character of some important track points scratched out. Thus, with the same energy, the new dot-matrix laser printer prints faster.

-

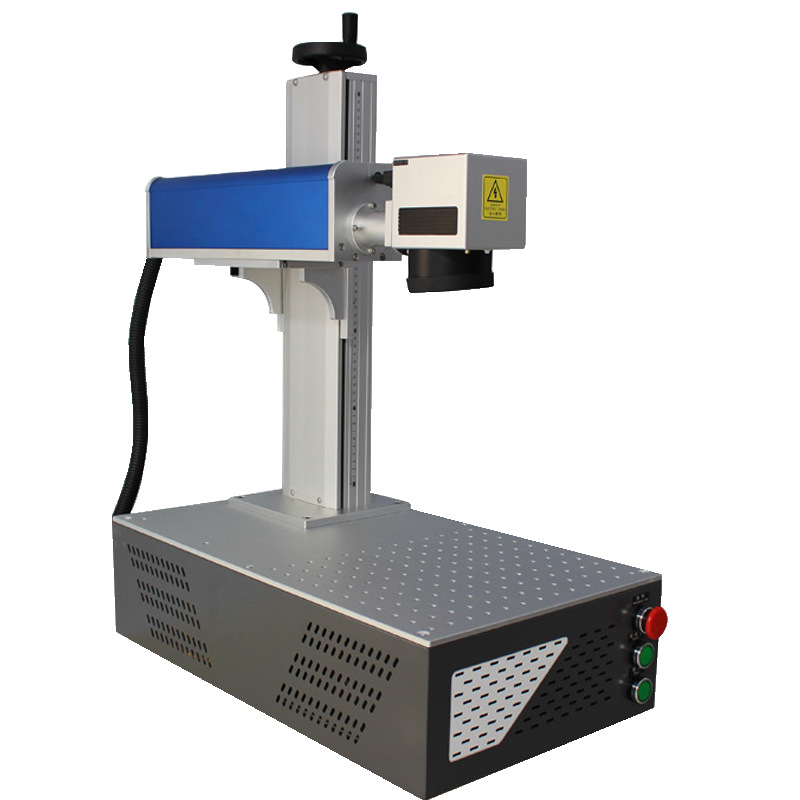

Fiber laser marking machine

The working principle of the laser coding machine is to gather the laser at a very high energy density on the surface of the object to be engraved. By burning and etching, the material on the surface is vaporized, and the effective displacement of the laser beam is controlled.

According to the different marking forms, laser marking equipment can be divided into two types: marking type and dot matrix type. At present, most laser coding equipment in the market is marked, but Markon’s laser coding equipment is using a new lattice technology – lattice resident technology. Marking laser machine is mainly to mark the character of the track completely scratched out, and dot-matrix laser machine is to mark the character of some important track points scratched out. Thus, with the same energy, the new dot-matrix laser printer prints faster.

-

Two axis rubber roller rolling machine

This machine is an automatic two-axis plate winding machine, mainly used in the operation process of bending, at room temperature, the plate winding machine can be rolled into a cylindrical shape, punching plate round – hole round – section arc.

The upper roll is lifted and pressed by the motor through the reducer, transmission shaft, worm gear and worm pair, screw nut pair to transfer power, resulting in bending deformation of the steel plate. Coil drive through the main motor through the main reducer, open gear drive roller rotation, and become the driving roller when rolling plate. Because the lower roller elevation is unchanged, it is easy to feed and operate. Is a very general equipment, is the boiler, shipbuilding, petrochemical, cement, electric machine manufacturing of the main key equipment. The equipment has the advantages of simple structure, compact, convenient operation and high efficiency. The product roundness deviation is less than 0.5mm, the lower roll of the winding machine adopts hydraulic cylinder, which can not only ensure the smooth movement process, but also stable pressure during the rolling process, so as to ensure that the distance between the lower roll and the upper roll is constant. In the whole product forming process, the material deformation degree of each smiling distance is less than 0.5mm

-

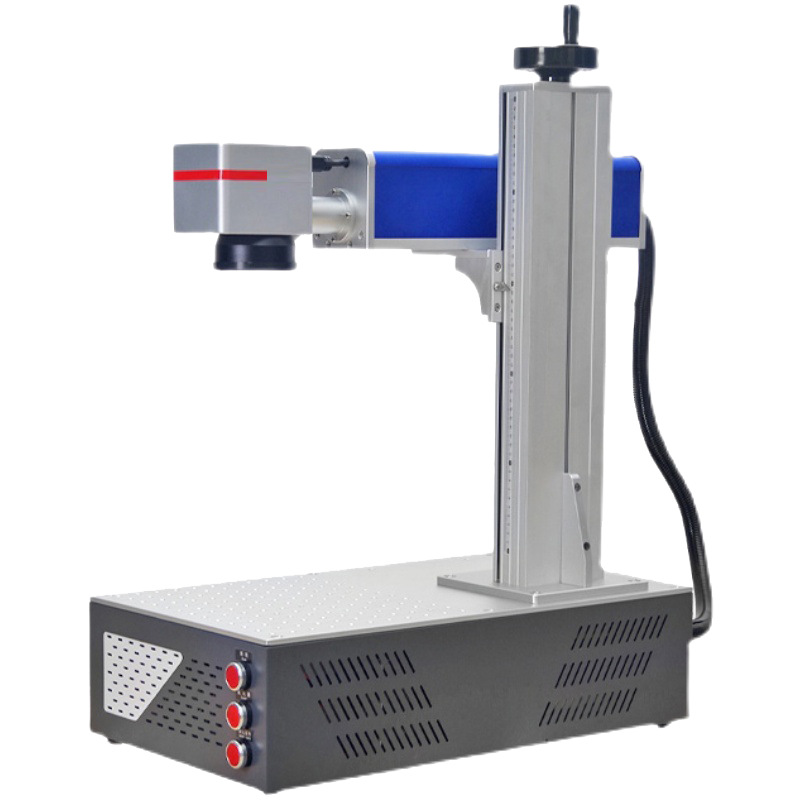

Desktop optical fiber marking machine

The working principle of the laser coding machine is to gather the laser at a very high energy density on the surface of the object to be engraved. By burning and etching, the material on the surface is vaporized, and the effective displacement of the laser beam is controlled.

According to the different marking forms, laser marking equipment can be divided into two types: marking type and dot matrix type. At present, most laser coding equipment in the market is marked, but Markon’s laser coding equipment is using a new lattice technology – lattice resident technology. Marking laser machine is mainly to mark the character of the track completely scratched out, and dot-matrix laser machine is to mark the character of some important track points scratched out. Thus, with the same energy, the new dot-matrix laser printer prints faster.

-

Small one-piece code machine metal stainless steel nameplate engraving machine, portable fiber laser marking machine

The working principle of the laser coding machine is to gather the laser at a very high energy density on the surface of the object to be engraved. By burning and etching, the material on the surface is vaporized, and the effective displacement of the laser beam is controlled.

According to the different marking forms, laser marking equipment can be divided into two types: marking type and dot matrix type. At present, most laser coding equipment in the market is marked, but Markon’s laser coding equipment is using a new lattice technology – lattice resident technology. Marking laser machine is mainly to mark the character of the track completely scratched out, and dot-matrix laser machine is to mark the character of some important track points scratched out. Thus, with the same energy, the new dot-matrix laser printer prints faster.

-

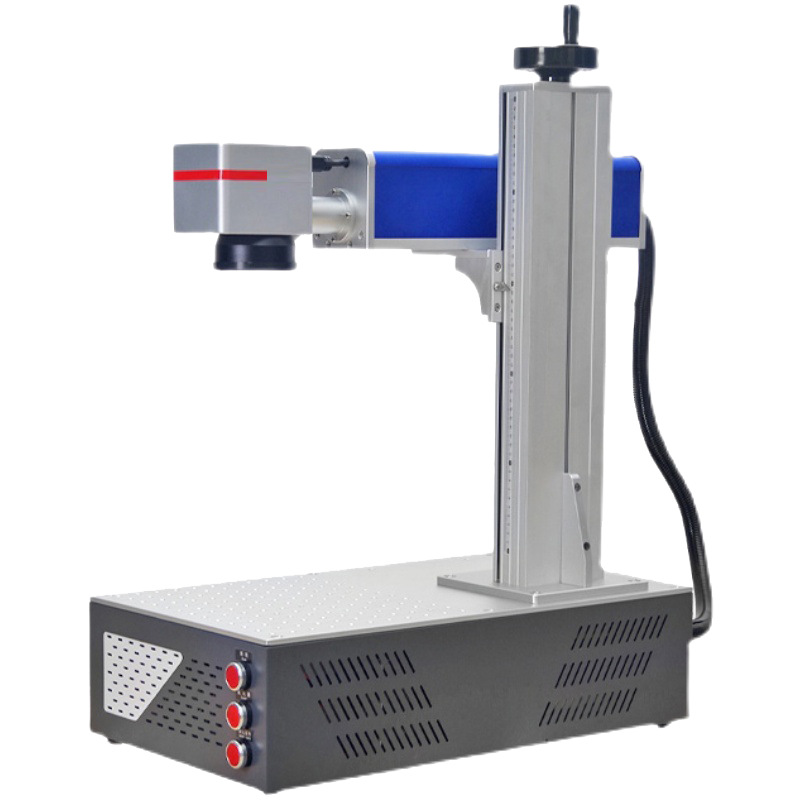

60w laser marking machine

The working principle of the laser coding machine is to gather the laser at a very high energy density on the surface of the object to be engraved. By burning and etching, the material on the surface is vaporized, and the effective displacement of the laser beam is controlled.

According to the different marking forms, laser marking equipment can be divided into two types: marking type and dot matrix type. At present, most laser coding equipment in the market is marked, but Markon’s laser coding equipment is using a new lattice technology – lattice resident technology. Marking laser machine is mainly to mark the character of the track completely scratched out, and dot-matrix laser machine is to mark the character of some important track points scratched out. Thus, with the same energy, the new dot-matrix laser printer prints faster.