Laser coating equipment series

-

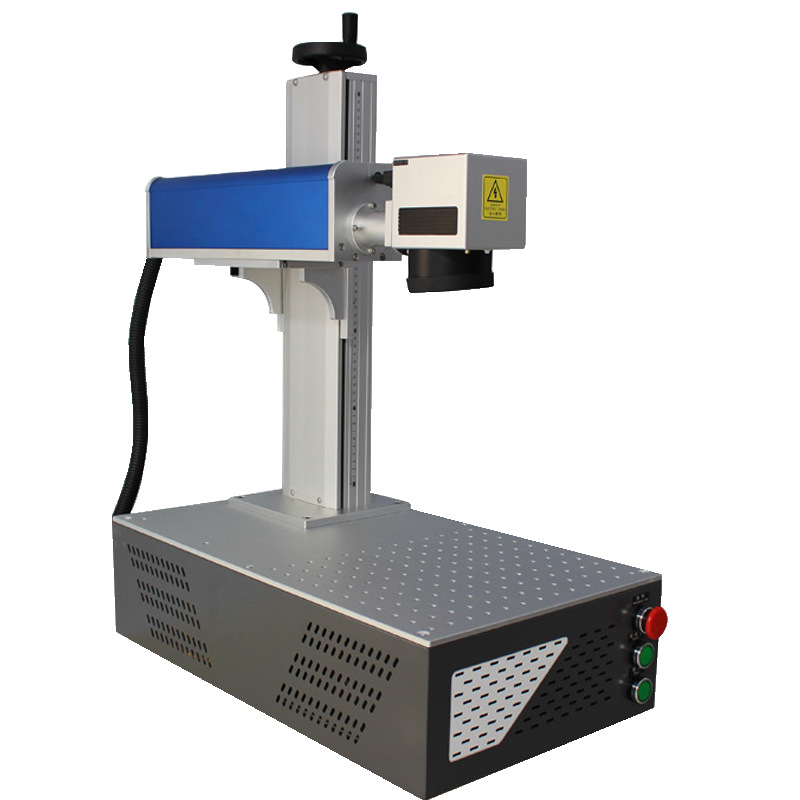

Factory direct laser marking machine 20W metal plastic stainless steel brass

Fiber laser marking machine is the use of laser beam on a variety of different substances on the surface of the permanent mark. Marking effect is through the evaporation of the surface material to reveal the deep material, or through the chemical and physical changes of the surface material caused by light energy to “carve” traces, or through the light energy to burn part of the material, showing the pattern, text, bar code and other graphics that need to be etched. The so-called fiber laser marking machine refers to the marking machine is the use of fiber laser, fiber laser has a small size (no water cooling device, the use of air cooling), good beam quality (fundamental mode), maintenance free and other characteristics.

-

30w laser marking machine

The working principle of the laser coding machine is to gather the laser at a very high energy density on the surface of the object to be engraved. By burning and etching, the material on the surface is vaporized, and the effective displacement of the laser beam is controlled.

According to the different marking forms, laser marking equipment can be divided into two types: marking type and dot matrix type. At present, most laser coding equipment in the market is marked, but Markon’s laser coding equipment is using a new lattice technology – lattice resident technology. Marking laser machine is mainly to mark the character of the track completely scratched out, and dot-matrix laser machine is to mark the character of some important track points scratched out. Thus, with the same energy, the new dot-matrix laser printer prints faster.

-

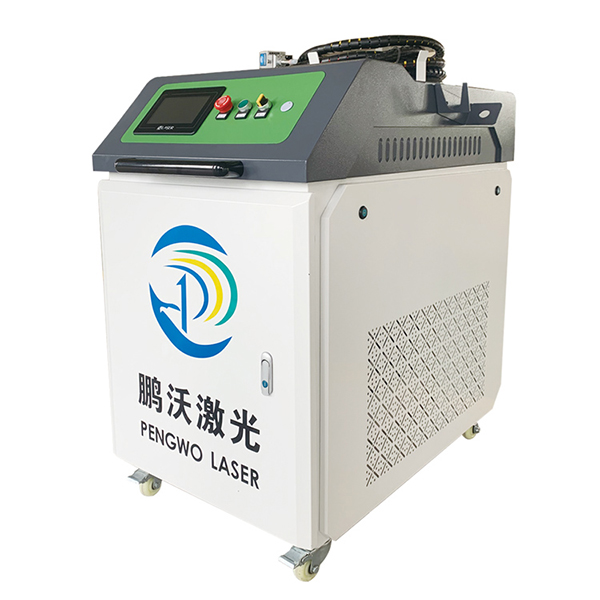

Laser cleaning machine handheld high power industrial oxidation layer cleaning machine pulse continuous laser rust remover

Non-contact cleaning, does not hurt the parts of the base material accurate cleaning, can achieve precise position, precise size selective cleaning, no chemical cleaning agent, no consumables, safety and environmental protection, simple operation, electricity can, cleaning efficiency is very high, save time, laser cleaning system is stable, almost no maintenance.

High efficiency, good effect, automatic operation, stable cleaning effect, do not need chemical cleaning solution. The interface of the host control system is clear, simple and easy to operate. A variety of parameters can be set to realize the control of the laser and galvanometer. Real-time monitoring of cleaning quality, real-time monitoring of cleaning effect, can achieve specific position, size cleaning.

-

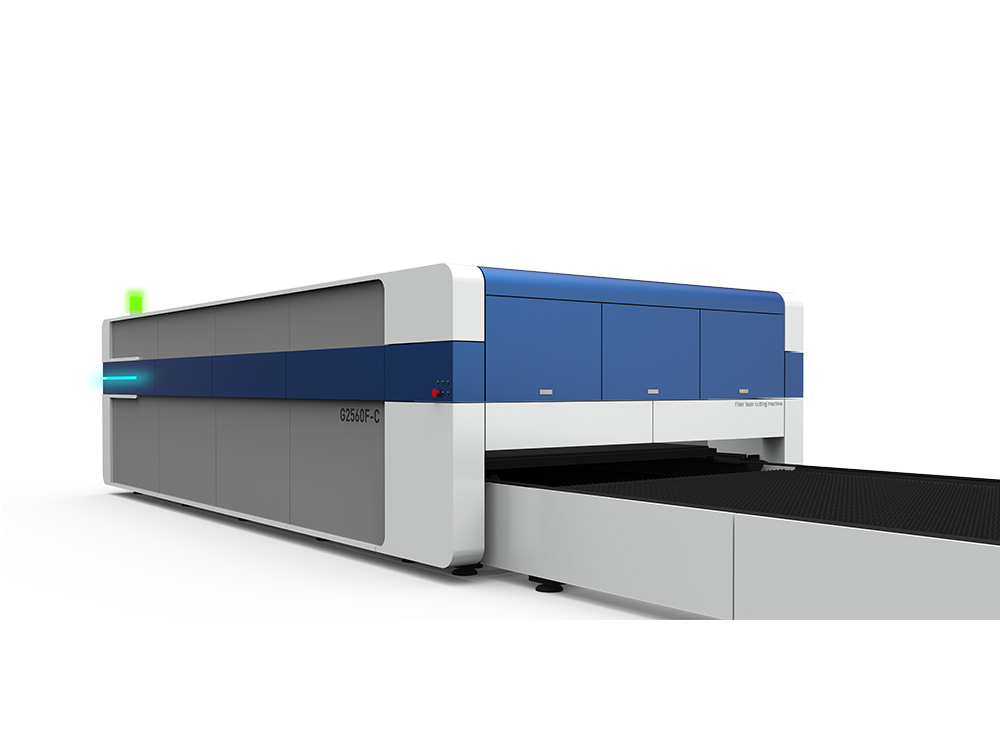

4000 watt closed switched laser cutting machine

ll-round 360 production line cutting group stop workflow, enabling automatic tube feeding, automatic feed, automatic cutting, automatic transmission operation.

2.Using KASRY Nesting programming system as a major programming tool, the software programming platform AUTOCAD basic, simple, graphical and intuitive, feature-rich, it can greatly improve operational efficiency.

-

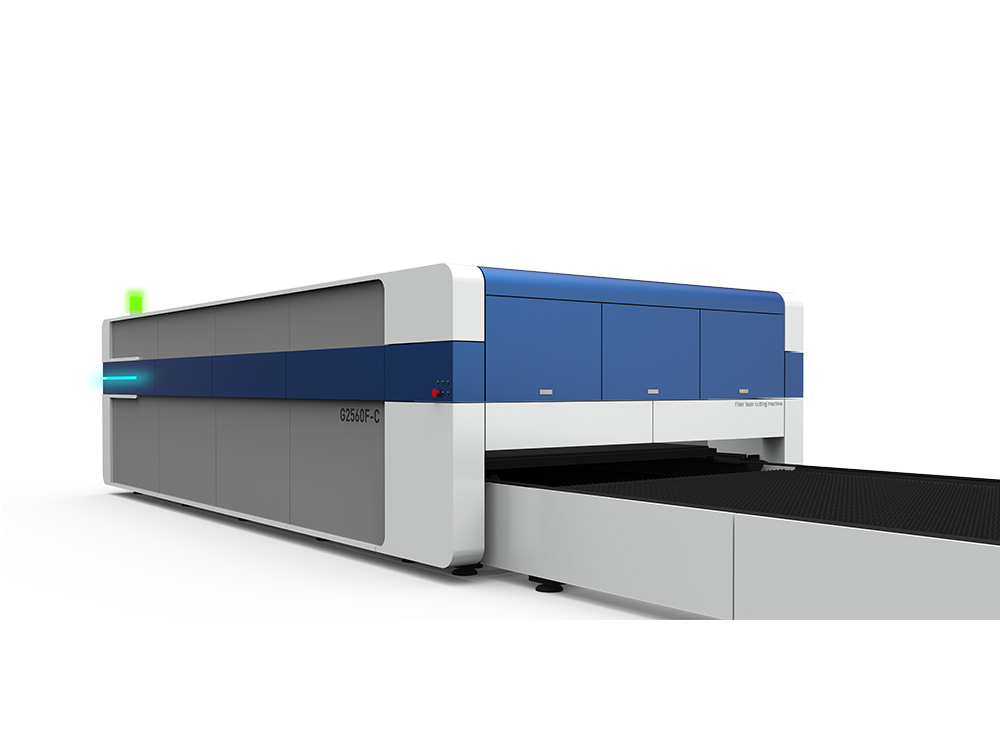

3000 W closed switched laser cutting machine

ll-round 360 production line cutting group stop workflow, enabling automatic tube feeding, automatic feed, automatic cutting, automatic transmission operation.

2.Using KASRY Nesting programming system as a major programming tool, the software programming platform AUTOCAD basic, simple, graphical and intuitive, feature-rich, it can greatly improve operational efficiency.

-

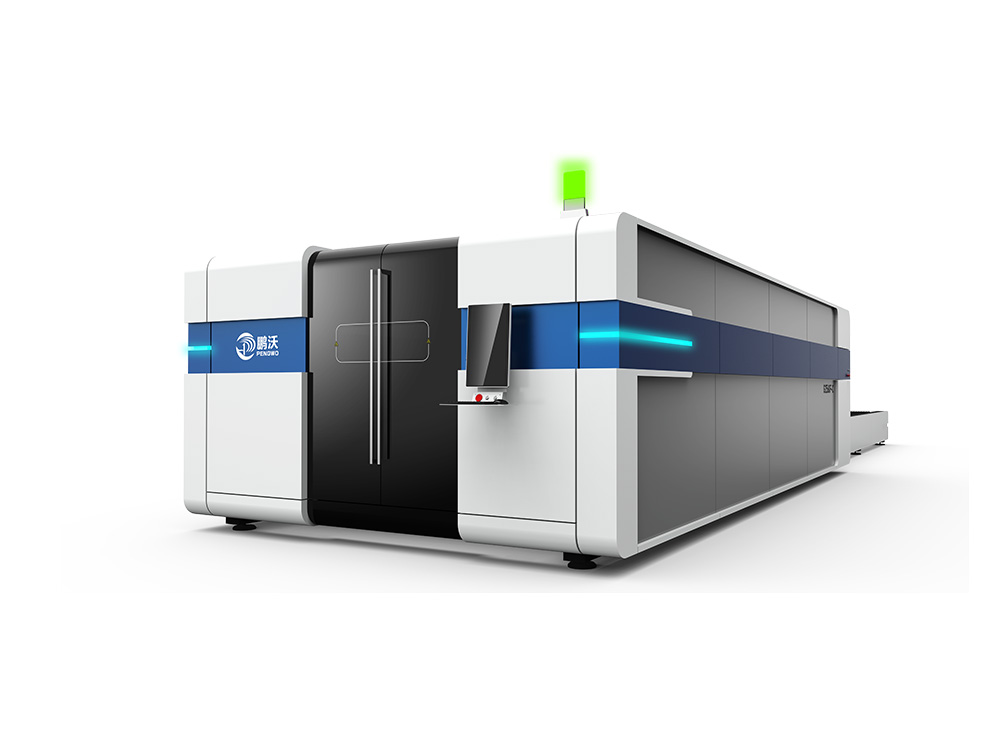

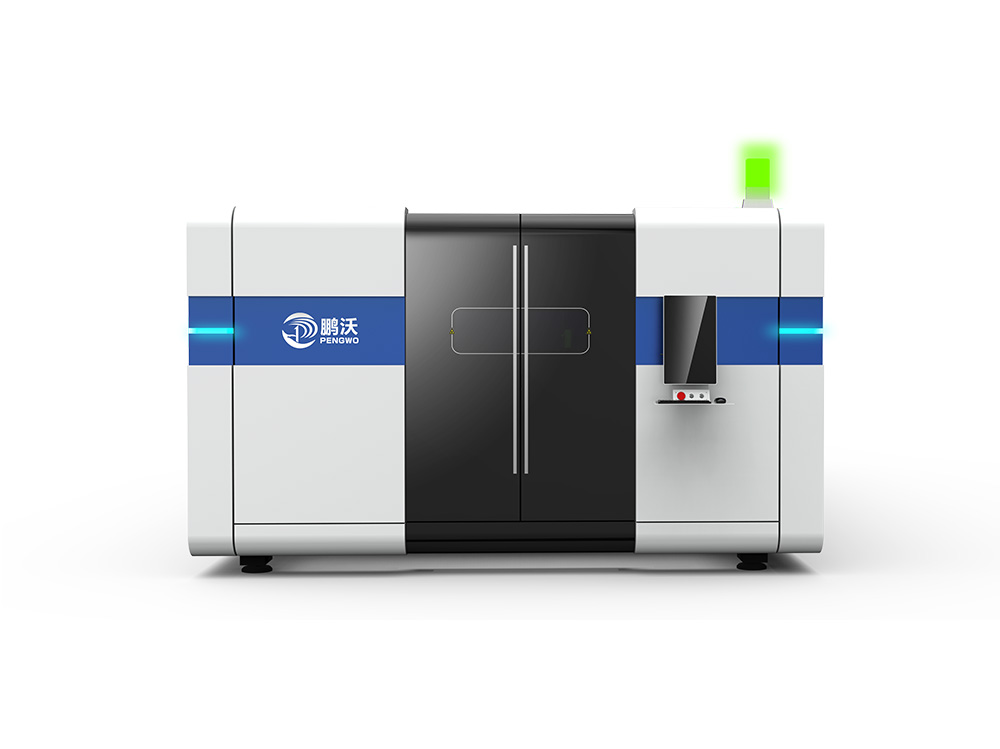

2040 Closed switched fiber laser cutting machine

2000W fiber laser is standard, 1000W-3000W fiber laser is optional, low operation and maintenance cost. Encircle design, in line with European CE standard, safe and reliable processing, configuration of exchange table, loading and unloading convenient, further improve production efficiency. According to the requirements of high speed movement, design and manufacture of reinforced welded bed, two effective treatment, to ensure the long-term operation of the bed precision and stability.Standard equipped with three air sources and double pressure air control system (high-pressure air, nitrogen, oxygen), to meet customers’ requirements for processing various materials, simple operation, lower cost. Standard metal professional automatic typesetting software (including material management, process optimization and other functions), provide process parameters library, so that the operator is simpler, easier to manage.Optimized optics, specially designed nozzles and sensor technology make cutting smoother and more stable. 2000mm x 4000mm and 2000mm x 6000mm worktables are available.

-

OEM printing personalized 12oz Kraft Paper Coffee Bags

The company independently designed gantry type CNC machine tool system, using high strength overall welding body, after high temperature annealing large CNC gantry milling machine precision machining;