Laser cutting machine series

-

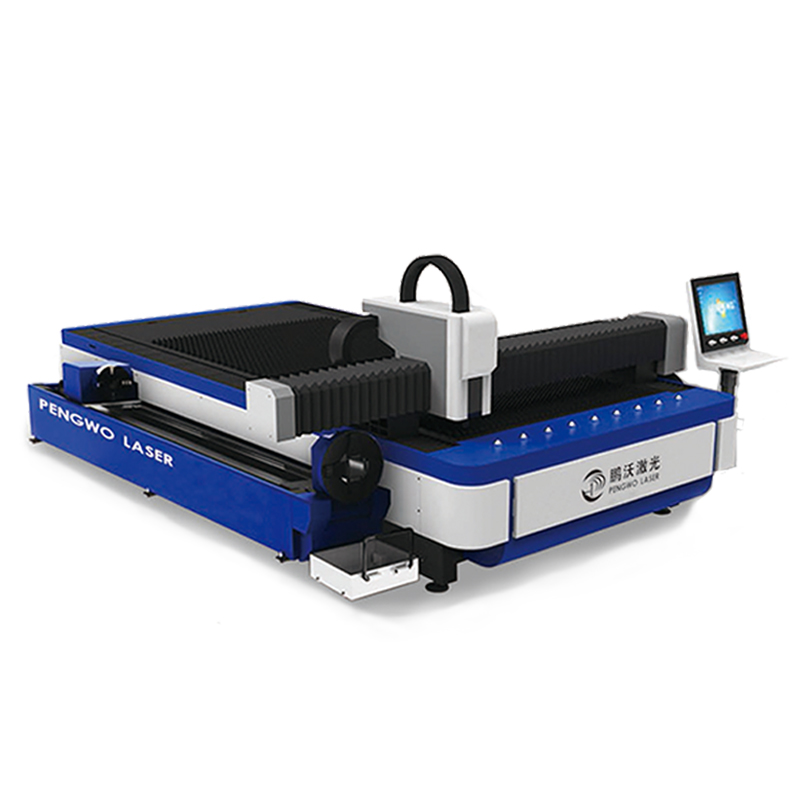

3000*1500mm CNC Laser Cutting Machine Fiber Laser Cutter Stainless Steel Sheet Tube Cutting With 1000W 2000W Laser Source

Excellent beam quality: smaller focusing spot, finer cutting lines, higher work efficiency, better processing quality; High cutting speed: is the same power CO, laser cutting machine 2 times; Extremely high stability: the world’s top imported fiber laser, stable performance, the service life of key components can reach 100,000 hours; Extremely high electro-optical conversion efficiency: optical fiber laser cutting machine photoelectric conversion efficiency of about 30%, is C0, laser cutting machine 3 times higher, energy saving and environmental protection; The power consumption of the whole machine is only 20-30% of the similar C0 laser cutting machine; Super flexible light guide effect: compact size, compact structure, easy to flexible processing requirements.The double ball screw closed-loop system and open CNC system enable high processing accuracy and high working efficiency during high speed cutting,while the man-machine interface is friendly.Can be equipped with different power of fiber laser: 500W/700W/1000W/1500W,etc.,operation and maintenance cost is low.Standard collocation of dual-pressuregascontrol system of 3 gas source (high pressure air, nitrogen and oxygen) meets the customer demand for a variety of materials processing, simple operation and lower cost.The software supports the input and output of general CAD (PLT, DXF, DST, AI, BMP, etc.) format file.

-

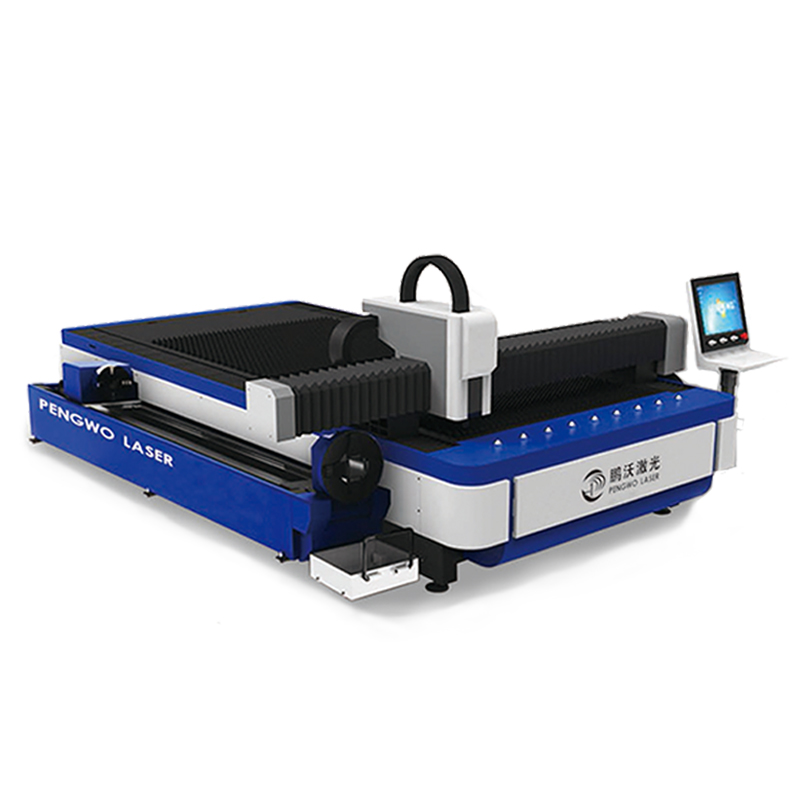

best price Raycus IPG 3015 1000w 1500w 2000w 3000w 6000w cnc metal metal fiber laser cutting machine

1.Equipped with raw material trays and finished material trays, which can realize automatic transfer back to the warehouse and meet the needs of small, medium, large, and varieties of plates.

* 2.Both the collimating lens and the focusing lens group are cooling accessories. Besides, the cooling airflow nozzle is added, which effectively protects the nozzle and the ceramics and prolongs the working time.

* 3.Without human interference, the focusing speed can reach 10m/min, and the repeatability is about 50 microns.

* 4.Adopting high-quality carbon steel welding bed, it has strong structural rigidity, small deformation, and low vibration toensure cutting accuracy. -

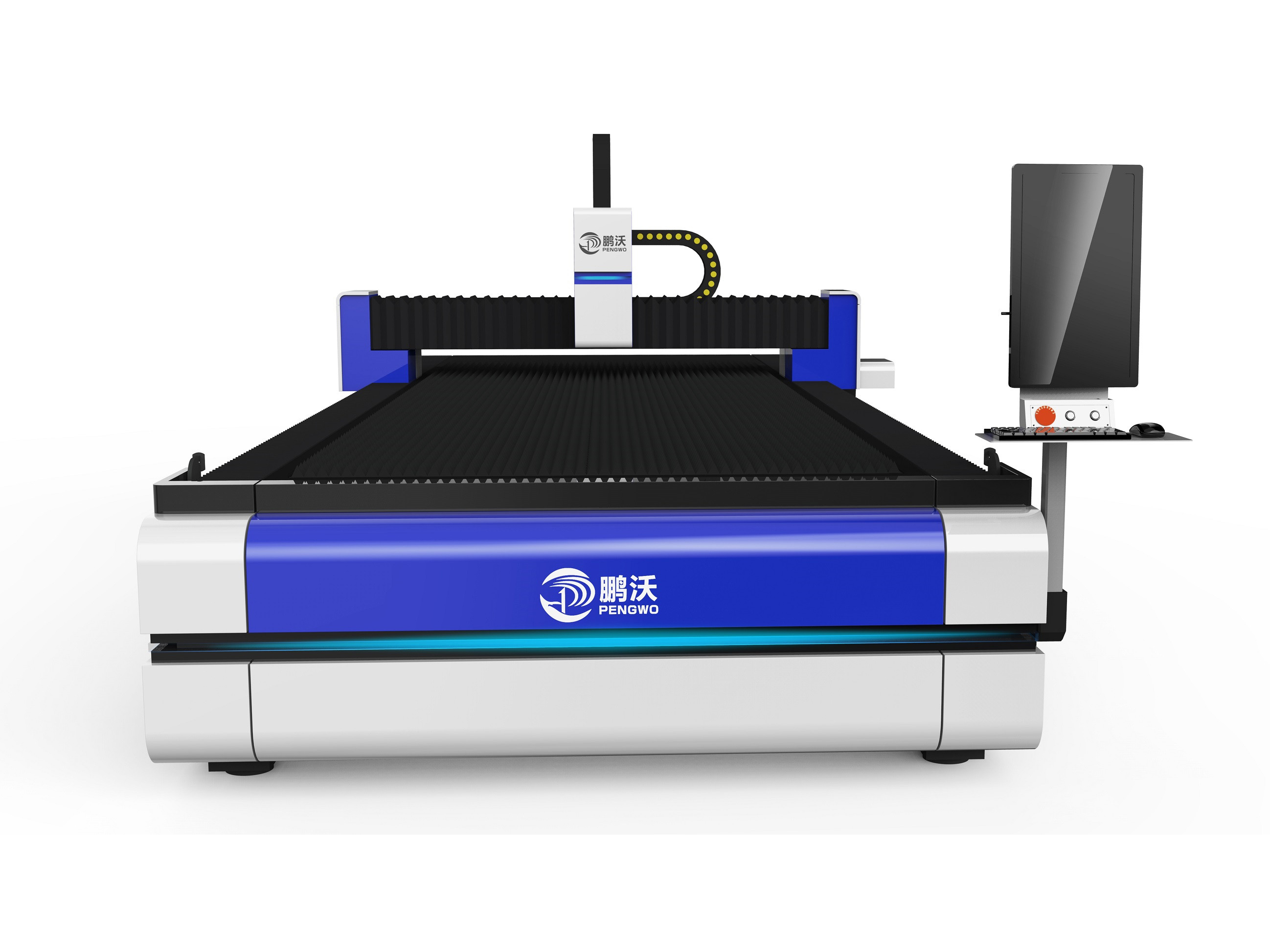

Oreelaser metal laser cutter CNC fiber laser cutting machine sheet metal

Machine Features:

1. High-performance laser device associated with stable operation system enables optimal cutting effects.

2. Perfect cooling, lubrication and dedusting systems ensure stable, efficient and durable performance of the whole machine.

3. Single countertop make plates loading and unloading available during cutting, which improves the processing eficiency.

4. Large-size closed enclosure improves dedusting effects and avoids optical pollution.

5. Automatic height-adjustment performance keeps constant focal length and stable cutting quality.

6. Gantry structure and inblock aluminum cast cross beam make the device highly rigid, stable and antiknock.

7. It could ut mental in various materials and realize excellent and stable cutting effects. -

Manufacturers supply 6000w open laser cutting machine

Excellent beam quality: smaller focusing spot, finer cutting lines, higher working efficiency, better processing quality; High cutting speed: is the same power CO, laser cutting machine 2 times; High stability: the world’s top imported fiber laser, stable performance, the service life of key components can reach 100,000 hours; High electro-optic conversion efficiency: optical fiber laser cutting machine photoelectric conversion efficiency of about 30%, is C0, laser cutting machine 3 times higher, energy saving and environmental protection; The power consumption of the whole machine is only 20-30% of that of the similar C0 laser cutting machine. Super flexible light guide effect: small size, compact structure, easy to flexible processing requirements.

-

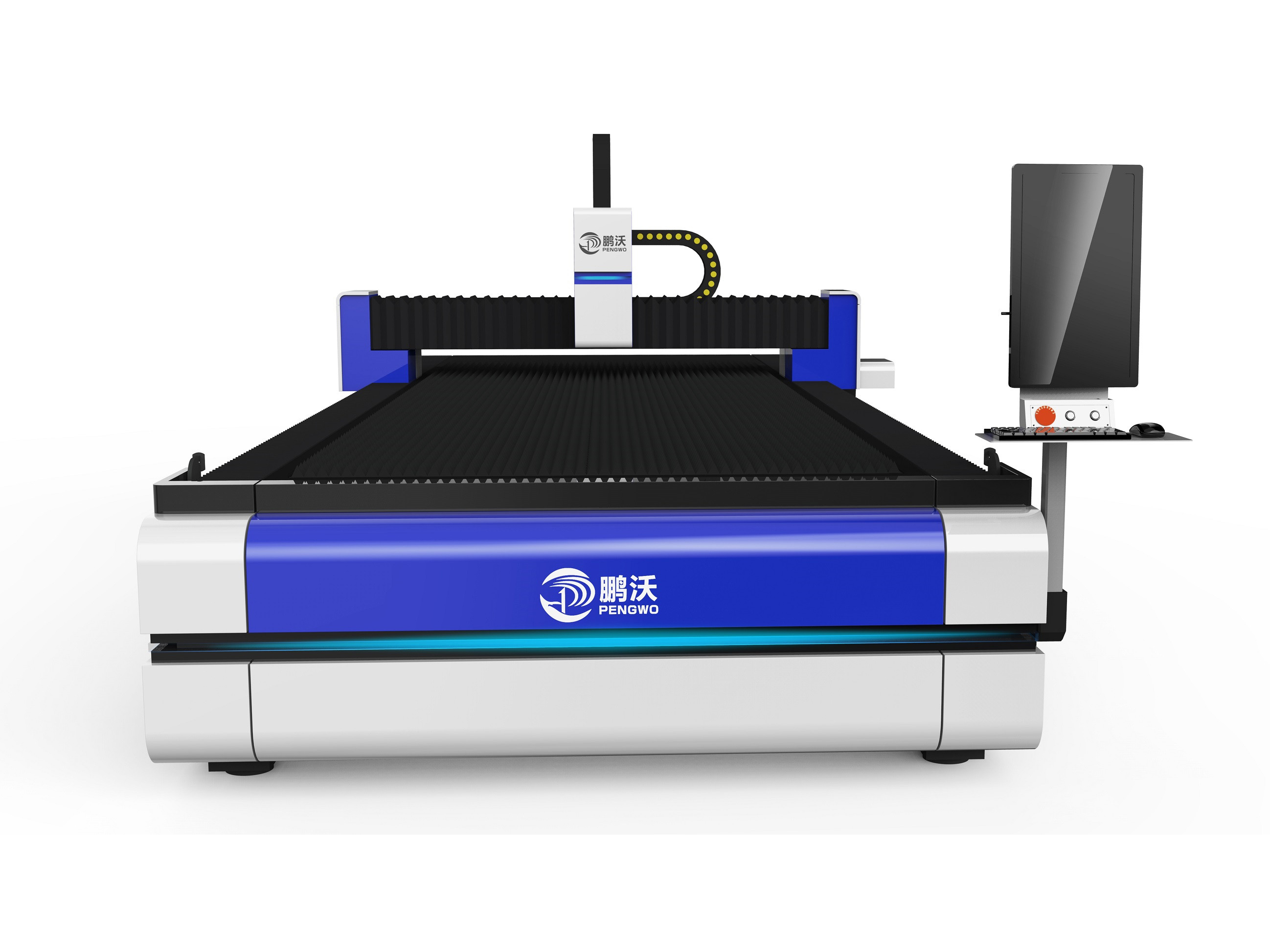

12000W high power single platform fiber laser cutting machine stainless steel laser cutting machine

Excellent beam quality: smaller focusing spot, finer cutting lines, higher working efficiency, better processing quality; High cutting speed: is the same power CO, laser cutting machine 2 times; High stability: the world’s top imported fiber laser, stable performance, the service life of key components can reach 100,000 hours; High electro-optic conversion efficiency: optical fiber laser cutting machine photoelectric conversion efficiency of about 30%, is C0, laser cutting machine 3 times higher, energy saving and environmental protection; The power consumption of the whole machine is only 20-30% of that of the similar C0 laser cutting machine. Super flexible light guide effect: small size, compact structure, easy to flexible processing requirements.

-

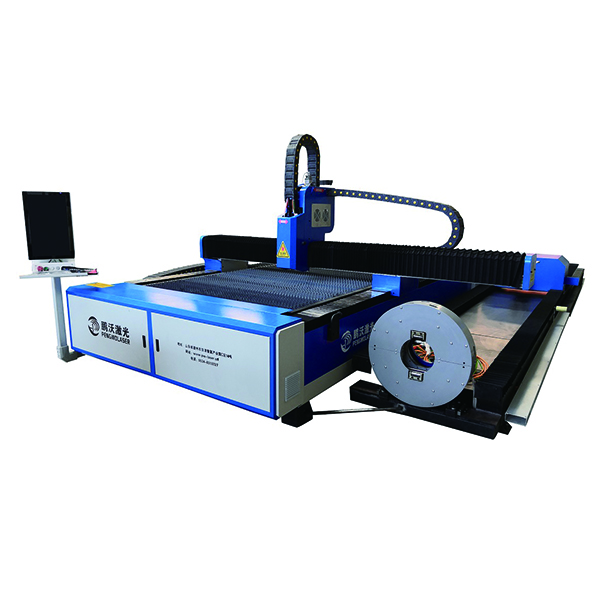

Plate and tube dual-use laser cutting machine can cut all kinds of plate and tube special-shaped tube

The machine adopts pinion and rack transmission structure, the standard manual clamping chuck, the propulsion-type tube cutting way, can be used for general sheet metal cutting and common square tube, round tube, rectangular tube cutting.

1. Powerful cutting function can meet customers’ requirements of plate and pipe cutting at the same time.

2. Adopt manual chuck and push cutting mode, with high centering accuracy and machining accuracy.

3. The machine tool adopts the overall profile welding structure which has been verified and analyzed by CAE for many times. Annealing to eliminate the internal stress after finishing, better solve the stress caused by welding and machining, thus improving the rigidity and stability of the equipment.

4. The gantry adopts high strength aluminum alloy integral casting structure, which has the advantages of light weight and good dynamic response.

5. X/Y axis adopts precise helical gear transmission mechanism to effectively ensure the precision and speed in the cutting process.

6. Better stability and longer service life. 7. Excellent processing system, friendly interface, easy to operate, and can be real-time feedback on the processing state, to ensure the orderly processing.

-

3000w open laser cutting machine

Excellent beam quality: smaller focusing spot, finer cutting lines, higher work efficiency, better processing quality; High cutting speed: is the same power CO, laser cutting machine 2 times; Extremely high stability: the world’s top imported fiber laser, stable performance, the service life of key components can reach 100,000 hours; Extremely high electro-optical conversion efficiency: optical fiber laser cutting machine photoelectric conversion efficiency of about 30%, is C0, laser cutting machine 3 times higher, energy saving and environmental protection; The power consumption of the whole machine is only 20-30% of the similar C0 laser cutting machine; Super flexible light guide effect: compact size, compact structure, easy to flexible processing requirements.The double ball screw closed-loop system and open CNC system enable high processing accuracy and high working efficiency during high speed cutting,while the man-machine interface is friendly.Can be equipped with different power of fiber laser: 500W/700W/1000W/1500W,etc.,operation and maintenance cost is low.Standard collocation of dual-pressuregascontrol system of 3 gas source (high pressure air, nitrogen and oxygen) meets the customer demand for a variety of materials processing, simple operation and lower cost.The software supports the input and output of general CAD (PLT, DXF, DST, AI, BMP, etc.) format file.

-

4000Wopen laser cutting machine

Excellent beam quality: smaller focusing spot, finer cutting lines, higher work efficiency, better processing quality; High cutting speed: is the same power CO, laser cutting machine 2 times; Extremely high stability: the world’s top imported fiber laser, stable performance, the service life of key components can reach 100,000 hours; Extremely high electro-optical conversion efficiency: optical fiber laser cutting machine photoelectric conversion efficiency of about 30%, is C0, laser cutting machine 3 times higher, energy saving and environmental protection; The power consumption of the whole machine is only 20-30% of the similar C0 laser cutting machine; Super flexible light guide effect: compact size, compact structure, easy to flexible processing requirements.The double ball screw closed-loop system and open CNC system enable high processing accuracy and high working efficiency during high speed cutting,while the man-machine interface is friendly.Can be equipped with different power of fiber laser: 500W/700W/1000W/1500W,etc.,operation and maintenance cost is low.Standard collocation of dual-pressuregascontrol system of 3 gas source (high pressure air, nitrogen and oxygen) meets the customer demand for a variety of materials processing, simple operation and lower cost.The software supports the input and output of general CAD (PLT, DXF, DST, AI, BMP, etc.) format file.

-

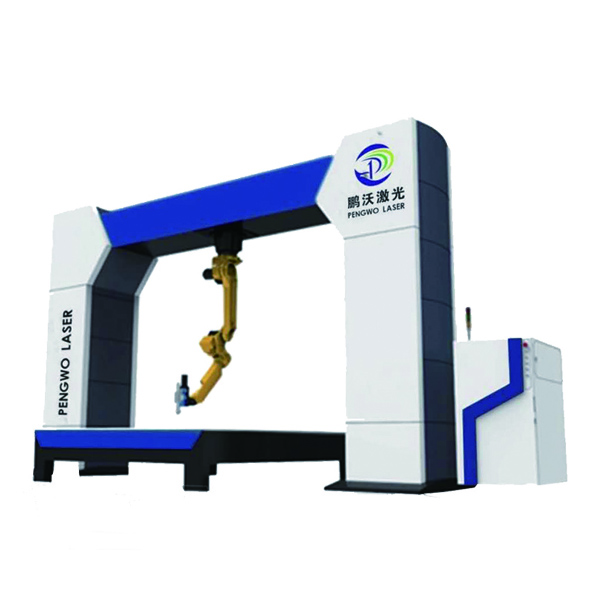

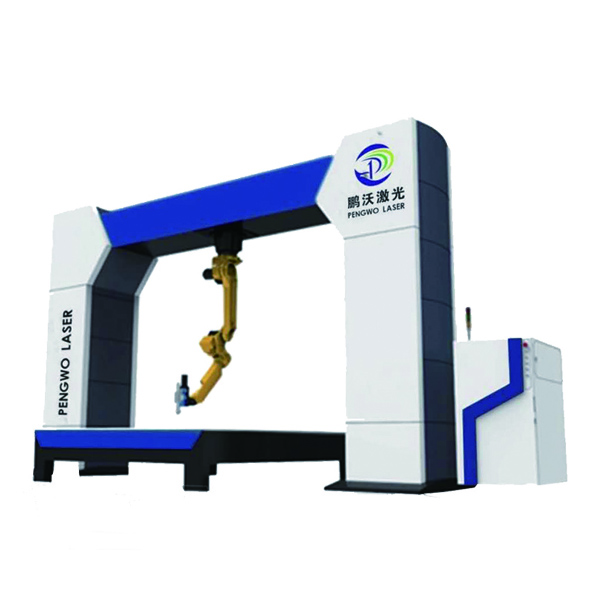

Factory supply 3D laser cutting machine

The perfect fusion of cutting-edge fiber laser and digital control technology represents the most advanced laser cutting level; The mechanical structure adopts imported manipulator, six axis linkage, the laser beam guide device is fully integrated in the robot arm, the advantages of the stable laser and the moving robot arm are combined, can realize the processing of arbitrary curves and specific curves in three-dimensional space, easy to operate, high degree of intelligence, greatly reduce the cycle time, to ensure the high speed of the equipment High precision and reliability; The combination of industrial robot and fiber laser processing, so that the processing process is completed in one time, the incision is neat without the post-process reprocessing, greatly shorten the process flow, reduce the labor cost and mold cost investment, but also improve the product grade and added value; Laser cutting head can withstand 1.0Mpa gas pressure, high pressure gas path equipment, improve the cutting ability of stainless steel and other difficult materials; The use of industrial robots has greatly reduced the cost of the system, reduced the cost of power consumption system and system operation and maintenance costs, reduce the footprint of the system.

-

Manufacturers supply 3D laser cutting machines

The perfect fusion of cutting-edge fiber laser and digital control technology represents the most advanced laser cutting level; The mechanical structure adopts imported manipulator, six axis linkage, the laser beam guide device is fully integrated in the robot arm, the advantages of the stable laser and the moving robot arm are combined, can realize the processing of arbitrary curves and specific curves in three-dimensional space, easy to operate, high degree of intelligence, greatly reduce the cycle time, to ensure the high speed of the equipment High precision and reliability; The combination of industrial robot and fiber laser processing, so that the processing process is completed in one time, the incision is neat without the post-process reprocessing, greatly shorten the process flow, reduce the labor cost and mold cost investment, but also improve the product grade and added value; Laser cutting head can withstand 1.0Mpa gas pressure, high pressure gas path equipment, improve the cutting ability of stainless steel and other difficult materials; The use of industrial robots has greatly reduced the cost of the system, reduced the cost of power consumption system and system operation and maintenance costs, reduce the footprint of the system.

-

Fiber laser board and tube integrated machine

Automatic lubricating system, convulsions automatically follow;

Board tube integration design, a whole casting type gantry structure, to ensure the high precision machining quality and efficiency;

Simple, efficient, professional CNC cutting system only needs one operator, save the human cost;

Rotating auxiliary apparatus design, to avoid the pipe surface when cutting different heart technical problem;Plate tube, round tube, square tube, rectangular tube cutting, has a great advantage, in solves the customer’s basic function, also can ensure the quality of our products

intelligent cutting system, specialized in cutting, automatic adjustment, convenient, practical, save materials, reduce the cost.

-

3000w large plate and tube laser all-in-one stainless steel aluminum plate metal plate and tube dual-use CNC laser cutting machine

Automatic lubricating system, convulsions automatically follow;

Board tube integration design, a whole casting type gantry structure, to ensure the high precision machining quality and efficiency;

Simple, efficient, professional CNC cutting system only needs one operator, save the human cost;

Rotating auxiliary apparatus design, to avoid the pipe surface when cutting different heart technical problem;Plate tube, round tube, square tube, rectangular tube cutting, has a great advantage, in solves the customer’s basic function, also can ensure the quality of our products

intelligent cutting system, specialized in cutting, automatic adjustment, convenient, practical, save materials, reduce the cost.