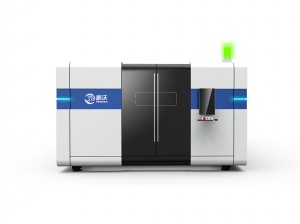

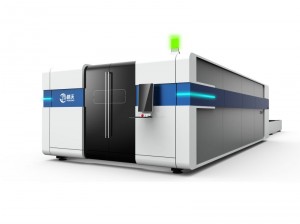

Stainless steel laser pipe cutting machine Round pipe square pipe shaped pipe all kinds of pipe metal laser pipe cutting machine

Cut sample drawing

Square steel, flat steel, channel steel, square pipe, steel, stainless steel, aluminum, alloy steel, aluminum alloy, carbon steel, stainless steel, copper, silver, gold, titanium, and other metal pipe cutting square pipe cutting

Application Industry

It is widely used in sheet metal processing advertising sign word production of high and low voltage electrical cabinet production of mechanical parts kitchenware automotive machinery metal crafts saw blade electrical parts eye industry spring plate circuit board electric kettle medical microelectronics hardware knife measuring tools and other industries

Advantages of Products

1. Multiple cylindrical intersecting line holes with different directions and diameters can be cut on the main pipe to meet the conditions of eccentric and non-eccentric vertical intersection between the main pipe axis and the main pipe axis (the main branch pipe are all round pipes).

2. The end of cylindrical intersecting line can be cut at the end of branch pipe to meet the conditions of eccentric and non-eccentric vertical intersection and oblique intersection between branch pipe axis and main pipe axis

3 Can cut a variety of graphics on the tube wall; It can cut the inclined cut face at the end of the pipe

4 can cut the end of the intersecting line of the branch pipe intersecting with the ring main pipe (the main branch pipe is round pipe); It can cut all kinds of shapes on the surface of square pipe

5. High precision, fast speed, narrow slit, minimum heat affected zone, smooth cutting surface without burr

6 Laser cutting head will not contact with the surface of the material, do not scratch the workpiece

7. The narrowest slit, the smallest heat affected zone, the workpiece local deformation is minimal, no mechanical deformation

8. Good processing flexibility, can be processed any graphics, can also cut pipe and other special-shaped materials

9 Can be steel plate stainless steel aluminum alloy plate hard alloy and other materials without deformation cutting

Product parameters

FAQ

The edge of cutting surface of plate and tube machine is seriously fused.

Laser output power is too large, laser cutting speed is too slow, auxiliary pressure is small, nozzle design is unreasonable

Sheet-tube machine. Alarm on cutting?

Software not working, host loose

Not turning on the cooling system resulted in excessive temperature in the laser cavity

The water pressure in the cooling system is too low and the water level is insufficient

Can't turn on the laser power?

The emergency stop switch is closed

Laser power supply damaged

Plate and tube integrated cutting machine, protective mirror pollution is very fast what reason?

1. Waste residue: It is mainly due to improper parameter setting, resulting in cutting waste residue backsplashing onto the lens. It can be solved by adjusting the process parameters of cutting or piercing, such as follow height, cutting pressure, laser pulse parameters, etc.

2. Oil stains or dust: auxiliary gas itself or gas circulation pipeline is polluted. It can be controlled by adding a filter device to filter oil or dust.

3. Water mist: generally caused by too large temperature difference. The ambient temperature is too high, and the cutting gas temperature is too low. The dew formation of the protective mirror in the ambient temperature can be properly adjusted so that the temperature of the two is about the same to solve the problem.

Plate and tube cutting, carbon steel heating reason?

1. cutting gas flow is small, can not be fully cooled on the copper nozzle. High pressure nitrogen gas can be used as auxiliary gas, high pressure nitrogen cooling effect is good.

2. No copper nozzle is used for cooling gas. ADAPTS the copper nozzle cooling gas can reduce the copper nozzle heat.

3. High focus cutting, laser easy to hit the small nozzle, so that the nozzle overheating. It is necessary to adjust the focus or increase the nozzle diameter when the nozzle is not hot.

4. Carbon steel in cutting, oxidation reaction, produce a lot of heat. This situation is unavoidable, and the distance between the nozzle and the material can be adjusted appropriately.