Manufacturers supply single platform fiber laser cutting machine metal laser cutting machine open laser cutting machine

Applicable materials

Stainless steel, carbon steel, alloy steel, spring steel, copper plate, aluminum plate, gold, silver, titanium and other metal plates

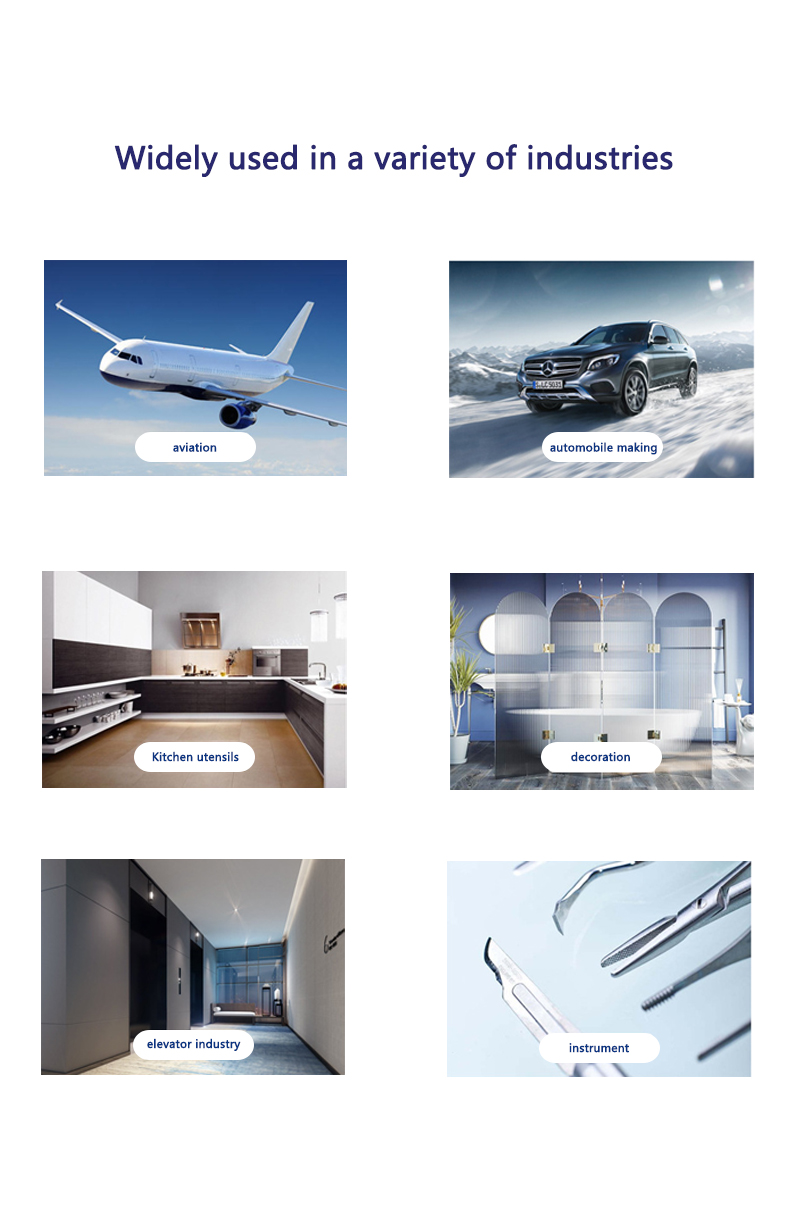

Application Industry

It is widely used in sheet metal processing advertising sign word production of high and low voltage electrical cabinet production of mechanical parts kitchenware automotive machinery metal crafts saw blade electrical parts eye industry spring plate circuit board electric kettle medical microelectronics hardware knife measuring tools and other industries

Advantages of Products

1.Use large gantry machining center precision machining equipment lathe bed; By the large gas car type heating furnace annealing heat treatment to eliminate the internal stress of welding lathe bed, so that the equipment to achieve higher precision and higher stability

2.Professional typesetting nesting software and professional laser cutting system is highly integrated, graphic intelligent typesetting, automatic cutting edges smooth edge cutting and processing function, can realize high speed blasting perforation and high-speed scanning array graphics cutting function

3.Machine adopt gantry double pinion and rack and double servo motor drive, large output torque, high moment of inertia, effectively improve equipment production efficiency;

4.Equipment has power failure memory function; The fallback cutting function: automatic fault alarm, emergency stop function; The trouble will automatically display function;

5.Laser cutting head with automatic focusing function, make punch than ordinary cutting head greatly shorten the time, especially suitable for thick plate of high-speed cutting.

Cut sample drawing

Product parameters

Partners

FAQ

The difference between laser cutting machine and plasma cutting machine

It works differently,Laser cutting machine is the laser emitted by the laser through the optical path system focused into a high power density laser beam.

The laser beam shines on the surface of the workpiece, so that the workpiece reaches the melting or boiling point.,At the same time, a high-pressure gas coaxial with the beam blows away the melted or vaporized metal.So as to achieve the purpose of cutting.

the advantages and disadvantages of laser cutting machine

the advantages of laser cutting machine:

(1) Laser cutting speed: sheet metal cutting speed up to 10m/min, much higher than plasma cutting machine.

(2) high cutting quality: small deformation, cutting table smooth. Laser cutting groove is very small, laser cutting surface without grinding can be directly used for welding.

(3) High cutting accuracy: laser cutting machine accuracy up to 0.05mm, repeat positioning accuracy up to 0.02mm.

(4) laser cutting materials a wide range of applications: metal and non-metal materials can be. There are metal laser cutting machines and CO2 laser cutting machines suitable for non-metals.

(5) Laser can also be used for engraving, welding, drilling and other other operations, powerful.