Pengwo automatic CNC Angle flange production line

Application Industry

Sheet metal processing, advertising sign word production, high and low voltage electrical cabinet production, mechanical parts, kitchenware, automobile, mechanical processing, saw blade, electronic parts, glasses industry, spring sheet, circuit board, electric kettle, medical electronics, hardware tools and other industries.

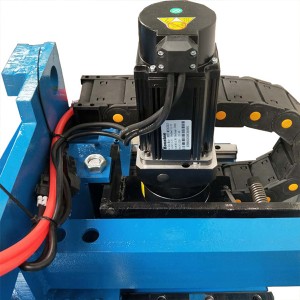

Detail drawing

Performance characteristics

CNC Angle flange production line has strong rigidity, compact structure, optimized discharge, shear free function, high material utilization rate; Punching, cutting, automatic, high production efficiency; Computer Chinese interface, easy to operate, can display the workpiece graphics; When compiling the program, only need to input the size of the workpiece, the distance, the number of work can be simple programming, but also can directly use the program data generated by the lofting software. A number of measures have been taken in the production line of NC Angle steel flange to solve the difficulty of feeding and the error of alignment caused by Angle steel bending. PLC, industrial computer control, servo motor feeding, high efficiency, stable working accuracy; The key liquid, gas, electric components are all imported products; With fault self-diagnosis and data statistics function.

1: new design, can realize the Angle steel end of the tail material within 400mm

2: using servo motor control, feeding size of

3: programming only need to input the size of the workpiece, large hole distance, the number of holes can be, simple operation

4: with production memory function, with the function of production order can be checked

Technical parameter

Main technical parameters 1: processing Angle steel range (mm) : 3-5 Angle steel 2: common punching size (mm) : large hole 9.5X13mm hole: 4.2/5.2mm 3: can be installed at the same time the number of punches (PCS) : 2 4: common Angle steel length: 6000mm 5: Machining accuracy: ≤0.5mm 6: Angle steel feeding speed: 15-20m/min

Safe operation procedure

1.Nc Angle flange production line safety operating rules: 1. Before taking the job, the operator must carry out job training, be familiar with the operation manual of the equipment, and understand the structure and performance of the machine.

2. Numerical control Angle steel flange production line structure performance is more complex, and belongs to the valuable large equipment, should be special, special post, not without a license operation.

3. The NC Angle steel flange production line is automatically controlled by computer, and the operator should operate strictly according to the instruction manual.

4. The production line of NC Angle steel flange is strictly prohibited from starting work with the air pressure lower than 0.35Mpa and the oil temperature higher than 65℃. When the oil temperature is higher than 45℃, the water cooling system should be started.

5. When the operator is working on the machine, do not stay away from his own post. If it is necessary to stay away from the machine due to special circumstances, the machine should be stopped and the power should be cut off.

6. In the working process of the CNC Angle steel flange production line, waste heads and beans should be eliminated in time to prevent the machine from being blocked and affect the normal work of the machine.

7. CNC Angle steel flange production line is not allowed to get close to the turning frame when working or adjusting. Non-operators are not allowed to enter the working area of the material frame (blank material frame, finished material frame).

8. When there is blank on the feeding road, it is forbidden to start the turning device. During the process of feeding the clamp into the car or withdrawing the clamp rod from the main engine, it is forbidden to press the clamp button. When the CNC car lifts the clamp rod back, it is forbidden to press the clamp button halfway.

9. When the machine is working, it is strictly prohibited to pass from the safety bar. Without special circumstances, it is strictly prohibited to lift the safety bar before the shearing machine.

10. In this NC Angle steel flange production line, guardians must be set up when adjusting and replacing the font, box, punch, negative die, shearing blade and adjusting the blade clearance. No one is allowed to press the button.

11. The hydraulic system valve of this machine (before delivery) has been adjusted. If it needs to be adjusted, it should be adjusted by professionals.

12. The pressure oil of the hydraulic system should be replaced regularly according to regulations, and unfiltered oil is strictly prohibited from entering the tank.

13. Do not insert a private tape disk into the drive to avoid computer viruses into the computer.

14. Shear blades, punching die frames, printing slide frames and moving parts are lubricated with No. N46 mechanical oil before each start.

15. Punching guide rail surface and screw main oil injection once per shift, transmission rack and measuring rack and measuring rack joint surface to be often coated with lubricating grease lubrication.

Partners

Technical exhibition

Certificate of Honor