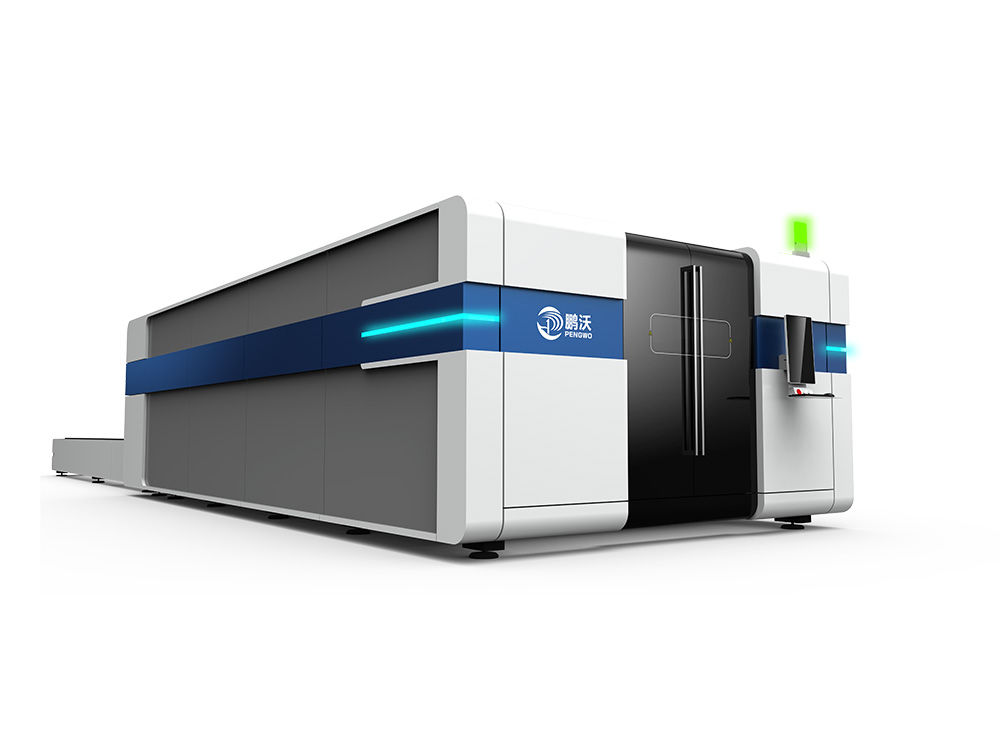

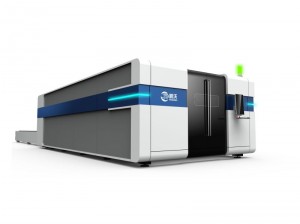

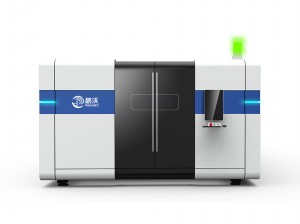

closed switched fiber laser cutting machine

Application

1.all-round 360 production line cutting group stop workflow, enabling automatic tube feeding, automatic feed, automatic cutting, automatic transmission operation.

2.Using KASRY Nesting programming system as a major programming tool, the software programming platform AUTOCAD basic, simple, graphical and intuitive, feature-rich, it can greatly improve operational efficiency.

Application

3.High-end three-dimensional flexible robotic cutting applications, to achieve bevel cutting function, the pipe and the torch using the servo positioning function .

Application

Can cut carbon steel, stainless steel, copper, aluminum and other pipes and profiles, such as: the tube, pipe, oval pipe, rectangular pipe, H-beam, I-beam, angle, channel, etc. The device is widely used in various kind of pipes profile processing field, shipbuilding industry, network structure, steel, marine engineering, oil pipelines and other industries.

Specification

FAQ

Closed laser cutting can not cut through.

Laser power decline or tube aging, laser cutting speed is too fast, focusing mirror or mirror pollution, focusing mirror cracking, focusing effect is poor, focal length adjustment is inappropriate, laser optical path is incorrect voltage instability, laser current is small

The reflective rate of the cut material is very high, the light outlet of the nozzle is blocked, the auxiliary gas pressure is too small, and the cooling effect of the cooling system is poor.

The starting point and the focus of the cut closed line do not coincide

There is loosening between the gear and shaft in the working table, the X axis and Y axis guide rail is not vertical, the transmission belt of X and Y axis is loose L, the gap between the slider and guide rail is too large L, the ruler belt is too loose, and the reverse gap is generated

The closed laser head produces no light source

The laser power decreases or the lamp is aged, the laser output energy is too low, and the optical path is deflected due to loose screws in the laser cutting head

There is more dust in the laser cavity, which pollutes the diaphragm frame, and the cooling system is opened for a long time without opening the laser power supply, resulting in ice and no light

The table jumps in the closed cutting process

The transmission belt is permanently deformed, the transmission gear groove has dirt, the tooth is not correct, the small gear groove of the size reduction gear has dirt

The cut size is too large

The pulse number is not set correctly, the radius compensation is not set, and the factory parameters of the bed are not set correctly