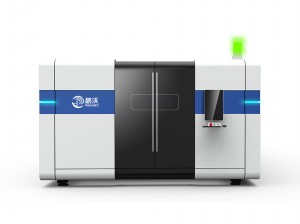

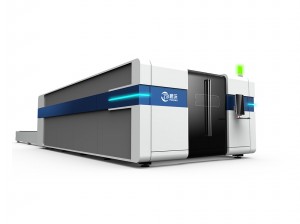

Metal closed exchange platform laser cutting machinePW-G-2060F-C

High-end intelligent bus cutting system

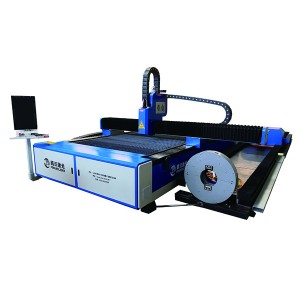

Widely used in advertising sign production, sheet metal structure, high and low voltage electrical cabinet Manufacturing, textile machinery parts, kitchenware, automobile, machinery, metal technology Product. Solution sheet, electrical parts, glasses industry, spring sheet, circuit board, Electric kettle, medical microelectronics, hardware, knife measuring tools and other industries.

Applicable materials: stainless steel, carbon steel, alloy steel, spring steel, copper plate, Aluminum sheet, gold, silver, titanium and other metal sheet.

High-end intelligent bus cutting system

Fine adjustment, High flexibility, well sealed、High stability, good cutting quality, speed perforation, complete the plate cutting of different thickness and material; Collimating and focusing using composite lenses, Optimal optical quality and cutting effect.

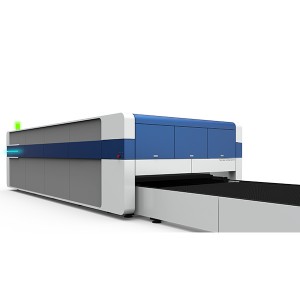

Heavy duty welding bed

Welded heavy steel plates, The prevailing bed structure, high stability, Using stress - relieving annealing technology, high mechanical strength, high temperature resistance, not easy deformation

The inner reinforcing bars of the tube are strengthened, four supports are added, and the high-speed operation is not shaken

Specification

FAQ

Closed laser cutting can not cut through.

Laser power decline or tube aging, laser cutting speed is too fast, focusing mirror or mirror pollution, focusing mirror cracking, focusing effect is poor, focal length adjustment is inappropriate, laser optical path is incorrect voltage instability, laser current is small

The reflective rate of the cut material is very high, the light outlet of the nozzle is blocked, the auxiliary gas pressure is too small, and the cooling effect of the cooling system is poor.

The starting point and the focus of the cut closed line do not coincide

There is loosening between the gear and shaft in the working table, the X axis and Y axis guide rail is not vertical, the transmission belt of X and Y axis is loose L, the gap between the slider and guide rail is too large L, the ruler belt is too loose, and the reverse gap is generated

The closed laser head produces no light source

The laser power decreases or the lamp is aged, the laser output energy is too low, and the optical path is deflected due to loose screws in the laser cutting head

There is more dust in the laser cavity, which pollutes the diaphragm frame, and the cooling system is opened for a long time without opening the laser power supply, resulting in ice and no light

The table jumps in the closed cutting process

The transmission belt is permanently deformed, the transmission gear groove has dirt, the tooth is not correct, the small gear groove of the size reduction gear has dirt

The cut size is too large

The pulse number is not set correctly, the radius compensation is not set, and the factory parameters of the bed are not set correctly