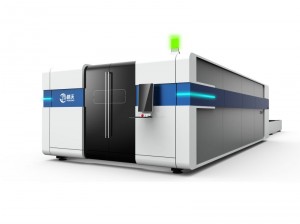

4000w open switched laser cutting machine

Product Description

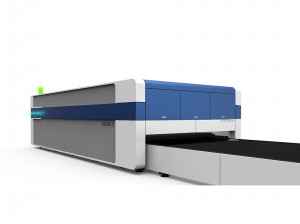

Using parallel exchange platform, bilateral drive with sprocket chain. It has the characteristics of stability, good rigidity and high speed. High-speed parallel switching platform design,Double work table exchange at the same time,Transmission mode is stable and reliable,The exchange time is shortened,Frequency converter is better. The movement speed is 140m/min. automatic tracking。 Automatic edge finding, automatic nesting, double efficiency, achieve smooth and beautiful cutting surface.

The beam adopts cast aluminum beam with high speed, precision and high efficiency Aluminum alloy has light weight,Rigid metal properties,Conducive to high speed movement in the processing process,High flexibility is conducive to high speed cutting of various graphics on the basis of high precision

Pipe welding lathe bed The internal structure of the bed is welded by multiple rectangular tubes. A reinforcing moment tube is arranged inside the bed. Add body strength and tensile resistance,Increase the tensile resistance and stability of the guide surface,Effectively avoid deformation of the bed. After aging treatment, the internal stress of the bed can be completely released. Its internal stress is almost negligible,Keep the precision of machine tool for a long time.

Independent electric control cabinet Electrical equipment assembly,Strong and weak electrical isolation,,Minimize circuit board T – disturbance. Easy to maintain,Good heat dissipation, dustproof, anti – static interference. Independent cabinet operation table style atmosphere, use spirit words,The position of the operating table can be adjusted at will. It is used in automobile, agricultural machinery, textile machinery, construction machinery, precision accessories, ships, metallurgical equipment, furniture, kitchenware, household appliances, metal crafts, hardware tools processing, decoration engineering, advertising signs, food gold processing and other industries

Plate welding lathe bed The special double-row flue flue is distributed on both sides of the bed, and the dust removal is divided into sections. Smoking is better,Can better meet the environmental requirements.

High-end intelligent bus cutting system

Stable and reliable, Easy to deploy, easy to debug, rich functions, computing power, algorithm, process flow, air travel control overall optimization

Perfect system function, greatly improve cutting efficiency and stability, improve the core competitiveness of equipment

High-end intelligent bus cutting system

Fine adjustment, High flexibility, well sealed、High stability, good cutting quality, speed perforation, complete the plate cutting of different thickness and material; Collimating and focusing using composite lenses, Optimal optical quality and cutting effect.

Heavy duty welding bed

Welded heavy steel plates, The prevailing bed structure, high stability, Using stress - relieving annealing technology, high mechanical strength, high temperature resistance, not easy deformation

The inner reinforcing bars of the tube are strengthened, four supports are added, and the high-speed operation is not shaken

Double combination smoke exhaust comprehensive purification of soot

◎Piecewise exhaust + sleeve flow fan negative pressure scanning

◎ Piecewise bed automatically induction laser cutting position, open accurate smoke exhaust

◎Axial flow fan enclosed downward blowing smoke, 360° strong long adsorption

◎ to create a hidden cavity open fully enclosed smoke control net smoke

Specification

FAQ

Open switch laser cutting machine Features:

1. Truss beam composite plate welding bed is made of truss beam and truss plate inserted. With high strength welding process, high temperature annealing stress, deformation prevention, low vibration, to ensure high cutting accuracy;

2. Based on the rigid-flexible coupling split-truss shaped aviation aluminum beam, the simulation is carried out under the actual working conditions, and the multi-source load from the beam's own acceleration and motor torque is carried out at the same time. The design of reasonable layout, high strength, strong stability, and ensure a long time and high speed cutting;

3. High strength worktable, easy to replace, no obstruction to production, efficient and time-saving, safe production;

4. Rich man-machine interaction interface, simple operation, easy to use.

Cutting range of laser cutting machine for open

Professional cutting 0.5-30mm carbon steel plate, stainless steel plate, 0.5-14mm galvanized plate, electrolytic plate, 0.5-16mm aluminum alloy, 0.5-10mm brass and coppwitch board:er and other metal materials.

Advantages of switching platform laser cutting machine:

1. Convenient loading and unloading, feeding and unloading at the same time, with 2-3 CNC operators can complete product production and processing;

2. A variety of processing materials, can be used to process a variety of metals, carbon steel, stainless steel and a series of plates;

3. No "tool" wear in the process of processing;

4. Non-contact processing, laser beam energy and moving speed can be adjusted, so you can complete a variety of processing, suitable for fine processing;

5. Easy to guide, and CNC system cooperate with each other, easy to operate;

6. Can continue to upgrade on the basis of the original cutting platform, with fully enclosed protective cover, can be fully enclosed processing, no pollution, small noise;

7. The system itself is a set of computer system, can facilitate the arrangement, suitable for characteristic processing, especially for some complex contour sheet metal parts, product life cycle is short, measured from the perspective of skills, economic costs and time, the production of molds is not cost-effective, laser cutting especially has advantages.

Does switching laser cutting work well?

Switching platform laser cutting machine equipment has a wide range of applications, flexible process, high processing accuracy, good quality, clean production process and easy to realize automation, flexibility, intelligence and improve product quality, labor productivity and other advantages.

Is the performance of switched laser cutting very stable?

The laser cutter in cutting process, the use of laser is very stable, the service life of the laser head for a few years, and in the process of using in addition to human factors, almost won't produce any fault system itself, so even if the laser cutting machine in the long time work under pressure, It doesn't produce any vibration or other adverse effects.