Nc Angle steel flange production line

Application Industry

Sheet metal processing, advertising sign word production, high and low voltage electrical cabinet production, mechanical parts, kitchenware, automobile, mechanical processing, saw blade, electronic parts, glasses industry, spring sheet, circuit board, electric kettle, medical electronics, hardware tools and other industries.

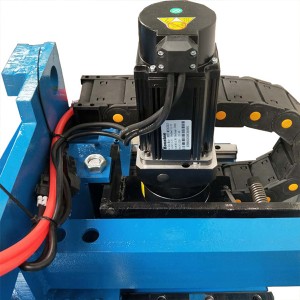

Detail drawing

Performance characteristics

1: new design, can realize the Angle steel end of the tail material within 400mm 2: using servo motor control, feeding size of 3: programming only need to input the size of the workpiece, large hole distance, the number of holes can be, simple operation 4: with production memory function, with the function of production order can be checked.

1. This machine tool system is a special system developed by our company based on the famous domestic brand industrial grade computer.

2. The hardware part of the system has strong anti-seismic and anti-interference ability. The machine tool with centralized lubrication system can adapt to long-term work, stable and efficient performance;

3. Precision servo motor drive, fast speed, short response time, large torque, accurate control, ensure the feeding processing precision, good performance;

4. Guide rail imported from Taiwan, high bearing capacity, good guidance;

5. Adopt high precision rack imported from Taiwan, accurate and stable feeding;

6. The machine adopts pneumatic clamp to prevent Angle steel slippage in the process of driving, which can fully ensure the clamping force.

Product advantage

CNC Angle steel flange production line adopts the cooperation of CNC system and stamping machinery to complete the punching and cutting action of Angle steel, forming a complete set of flexible automatic stamping production line, stamping workers are liberated from monotonous heavy and dangerous working state, to ensure safety and improve production efficiency. CNC Angle steel flange production line system is a special system developed by our company on the basis of industrial computers of famous domestic brands. The hardware part has strong anti-seismic and anti-interference ability, the machine tool with centralized lubrication system can adapt to long time work, stable and efficient performance; Precision servo motor drive, fast speed, short response time, large torque, accurate control, ensure the feeding processing precision, good performance; Guide rail imported from Taiwan, high bearing capacity, good guidance; Adopt high precision rack imported from Taiwan, accurate and stable feeding; CNC Angle flange production line with pneumatic clamp, to prevent the Angle steel slippage in the process of driving, can fully ensure the clamping force.

Technical parameter

Main technical parameters 1: processing Angle steel range (mm) : 3-5 Angle steel 2: common punching size (mm) : large hole 9.5X13mm hole: 4.2/5.2mm 3: can be installed at the same time the number of punches (PCS) : 2 4: common Angle steel length: 6000mm 5: Machining accuracy: ≤0.5mm 6: Angle steel feeding speed: 15-20m/min

Partners

Technical exhibition

Certificate of Honor