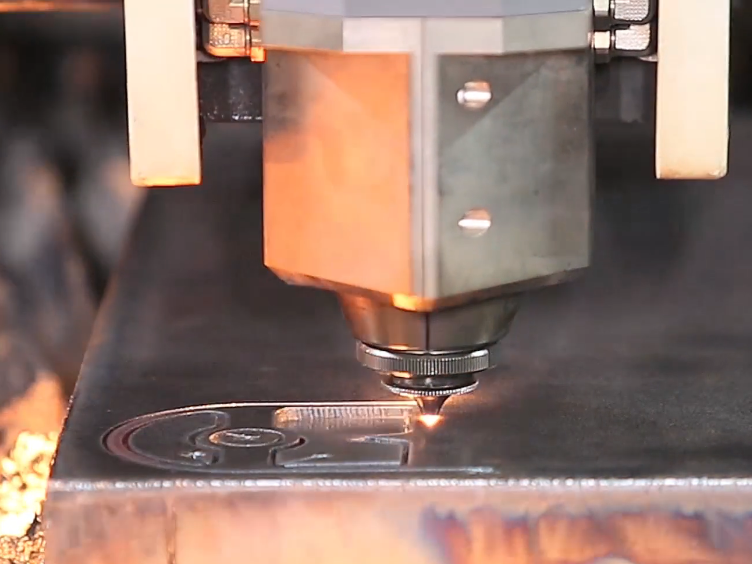

With the development of science and technology, all walks of life are also quietly changing, among them, laser cutting processing with invisible light beam instead of the traditional mechanical knife, laser cutting with high precision, cutting speed characteristics, not limited to cutting pattern restrictions, automatic typesetting save materials, and smooth incision, low processing cost, Laser cutting is gradually improving or replacing the traditional metal cutting process equipment.

Laser cutting machine is generally composed of laser generator, host frame, motion system, software control system, electrical system, laser generator, external optical path system. One of the most important is the laser generator, which directly affects the performance of the equipment. The transmission structure of laser cutting machine is generally synchronous wheel synchronous belt drive, synchronous belt drive is generally known as meshing belt drive, through the transmission belt inner surface equidistance distribution of transverse teeth and the corresponding tooth groove on the belt wheel meshing to transfer motion.

At present, the laser cutting machine on the market is a set of motion system for cutting operations, laser cutting head driven by the motor for X, Y, Z three directions of mobile cutting, can carry out a single motion trajectory of the graph for cutting.

With the continuous development of laser cutting technology, laser cutting processing capacity, efficiency, quality are constantly improving. But in the existing laser cutting machine for a set of motion system, in a single or single version of the laser cutting requirements of the pattern must be the same or mirror pattern, in the laser cutting typesetting has limitations, can only carry out a single single graphic typesetting corresponding to only a set of processing trajectory can be achieved, can not achieve the efficiency of the promotion.

To sum up, how to effectively solve the limitations of single graphics typesetting and low cutting efficiency is an urgent problem for technicians in this field.

Post time: Jul-31-2023