Intersecting line cutter

Application industry

Sheet metal processing, advertising sign word production, high and low voltage electrical cabinet production, mechanical parts, kitchenware, automobile, mechanical processing, saw blade, electronic parts, glasses industry, spring sheet, circuit board, electric kettle, medical electronics, hardware tools and other industries.

Applied materials

Stainless steel, carbon steel, alloy steel, spring steel, copper plate, aluminum plate, gold, silver, titanium and other metal plates

Product advantage

1 .is the accuracy, the traditional artificial hand-held plasma and flame cutting of various phases of the mouth, the longer the working time of the accuracy of the gap is also very much, there is a little attention will produce a great error our intersecting line cutting machine using Japanese Panasonic servo motor control operation, cutting operation precision

2. Cutting efficiency Manual cutting speed is slow, some places the error is larger or need to carry out secondary processing, production efficiency will be greatly reduced, each cutting also requires the size of the crossing line cutting machine directly with CAD to make cutting graphics, directly generate cutting code, do not need manual marking, direct cutting export type

3. When receiving a very large project, the transportation cost is also very large. The intersecting line cutting machine of our company adopts the process of the whole chassis, which is divided into 2-3 sections for convenient transportation Direct use

4. There is a fatigue period, many factors will lead to a decline in production efficiency, but the intersecting line cutting machine does not, as long as the cutting conditions can work 1-2 people can complete the operation, only the feeding level, the operation of the industrial control computer, the cutting workpiece can be picked up and finished

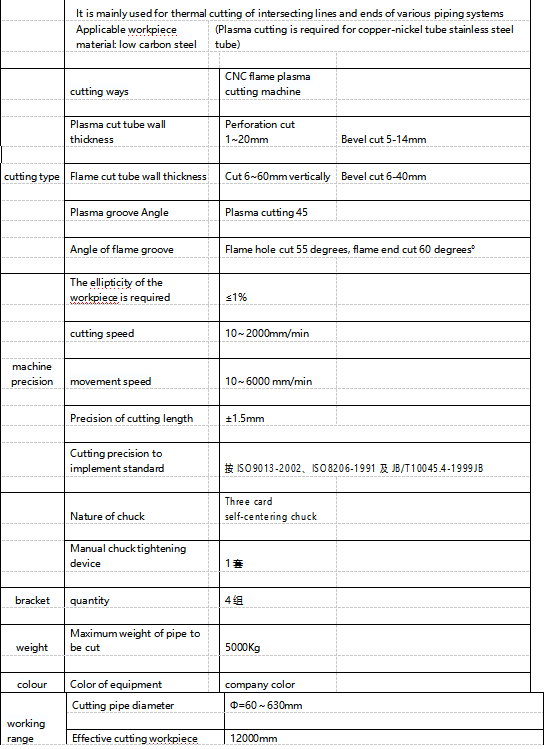

Detailed Parameters