Laser welding is one of the important components of laser material processing. Laser welding is a high energy beam as a heat source of a kind of precision welding technology, which is mainly through the high energy laser beam heating workpiece surface, heat from the surface of the material to the internal diffusion, through the adjustment of the laser pulse parameters, so that the corresponding material melting, forming a specific molten pool.

The principle of laser welding can be divided into heat conduction welding and laser deep penetration welding. Laser welding uses laser energy to combine materials of different materials, different thicknesses or different shapes to meet the requirements of material performance in different situations. It can realize the lightest weight, the best structure and the best performance of equipment.

So, what are the advantages of laser welding machine in the field of thin plate welding? The advantages of laser welding machine in the field of thin plate welding: stainless steel material is widely used in the manufacturing of various finished products, among which the welding of stainless steel sheet has become an important process in the production and manufacturing process. But because of the characteristics of sheet stainless steel itself, also caused a certain difficulty in welding, but also once became a welding problem in the field of sheet stainless steel. Traditional welding machine processing sheet stainless steel has a big problem, sheet stainless steel due to its thermal conductivity is very small, about only one third of ordinary low carbon steel, the constraint degree is small, so in the welding process once the local heating and cooling effect, will form uneven stress and strain, longitudinal contraction of the weld on the outer edge of stainless steel sheet produce a certain pressure, Once the pressure of the traditional welding machine is too large, it will cause the wavy deformation of the workpiece, which not only affects the appearance but also affects the quality of the workpiece. In addition, there will be the problem of over-burning and burning through.

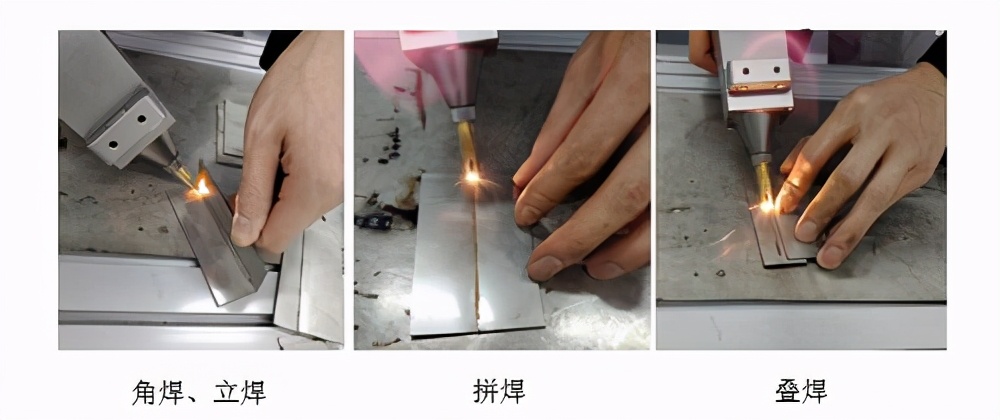

The appearance of fiber laser welding machine solves this problem well. Laser welding uses high energy laser pulse to heat the material locally in a small area. The energy of laser radiation diffuses to the interior of the material through thermal conduction, and the material is melted to form a specific molten pool. High welding depth to width ratio, small weld width, small heat-affected zone, small deformation, fast welding speed, smooth and beautiful weld, no processing or simple processing after welding, high quality weld, no porosity, accurate control, small focusing spot, high positioning accuracy, easy to realize automation. Laser welding machine with a number of advantages is gradually replacing the traditional sheet welding market.

Post time: Mar-25-2023