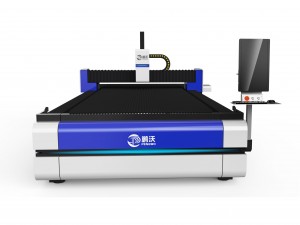

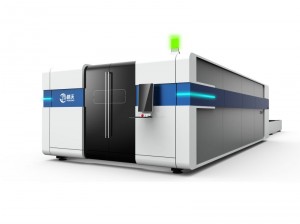

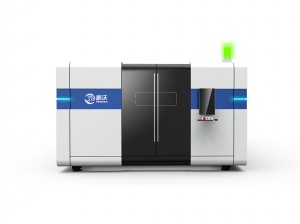

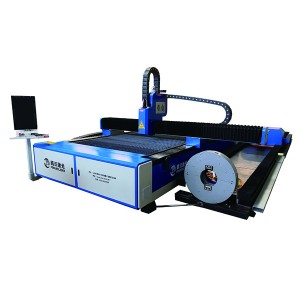

Open fiber laser cutting machine

Application industry

Sheet metal processing, advertising sign word production, high and low voltage electrical cabinet production, mechanical parts, kitchenware, automobile, mechanical processing, saw blade, electronic parts, glasses industry, spring sheet, circuit board, electric kettle, medical electronics, hardware tools and other industries.

Applied materials

Stainless steel, carbon steel, alloy steel, spring steel, copper plate, aluminum plate, gold, silver, titanium and other metal plates

Product advantage

1. Numerical control system: direct recognition of CAD drawings, graphics processing, parameter setting

2. Processing after stress removal by heat treatment

3. Anti-collision structure: work error will not damage the 3D laser cutting head

4. The fifth generation extruded aviation aluminum beam:Based on the rigid-flexible coupling analysis, the aviation aluminum beam formed by the simulation of the actual working conditions, while bearing multiple sources of load from the beam's own acceleration and motor torque, reasonable layout design, high strength, strong stability, to ensure a long time and high speed cutting;

5. Hollow PIPE WELDING BED STRUCTURE: THE bed adopts THE structure OF HOLLOW pipe WELDING bed which has been demonstrated and verified by CAE analysis for many times. The welding stress is eliminated by high temperature annealing and natural aging, deformation is prevented, the vibration is low and the cutting accuracy is guaranteed

Specification