Manufacturers supply 1500 watt hand-held laser welding machine

Application Industry

Sheet metal processing, advertising sign word production, high and low voltage electrical cabinet production, mechanical parts, kitchenware, automobile, mechanical processing, saw blade, electronic parts, glasses industry, spring sheet, circuit board, electric kettle, medical electronics, hardware tools and other industries.

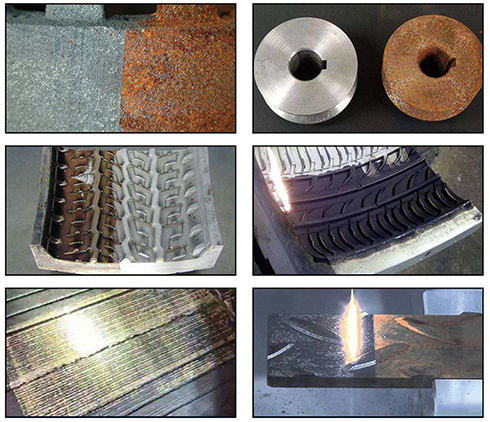

Effect drawing

Advantages of Products

1 can realize no dead Angle cleaning, such as edges and corners: optical devices make the laser beam quickly move back and forth on the workpiece can be used according to the required cleaning effect using different scanning graphics and speed linear scanning motion can be used for cleaning micro-pollution; If more in-depth cleaning is required, use an overlapping scan or jia large equipment power.

2 Precise positioning cleaning: the laser can clean the surface, such as aluminum carbon fiber composite or coated parts, without damaging the underlying material or, by choosing different parameter sets, the same laser can also rough the surface and improve the strength of the bond The flexibility of laser tools allows them to be applied to a variety of tasks as needed, and the cost of laser cleaning is approximately five times lower than that of comparable wet chemical cleaning processes.

3 Green cleaning options: cleaning not only refers to the laser cleaning effect is very clean, but also the cleaning process itself is a green environmental protection process and wet chemical process is different, he does not use toxic solvents and avoid the use of abrasive method generated noise and damage to the substrate.

Main accessories

Product parameters

Partners

Certificate of Honor