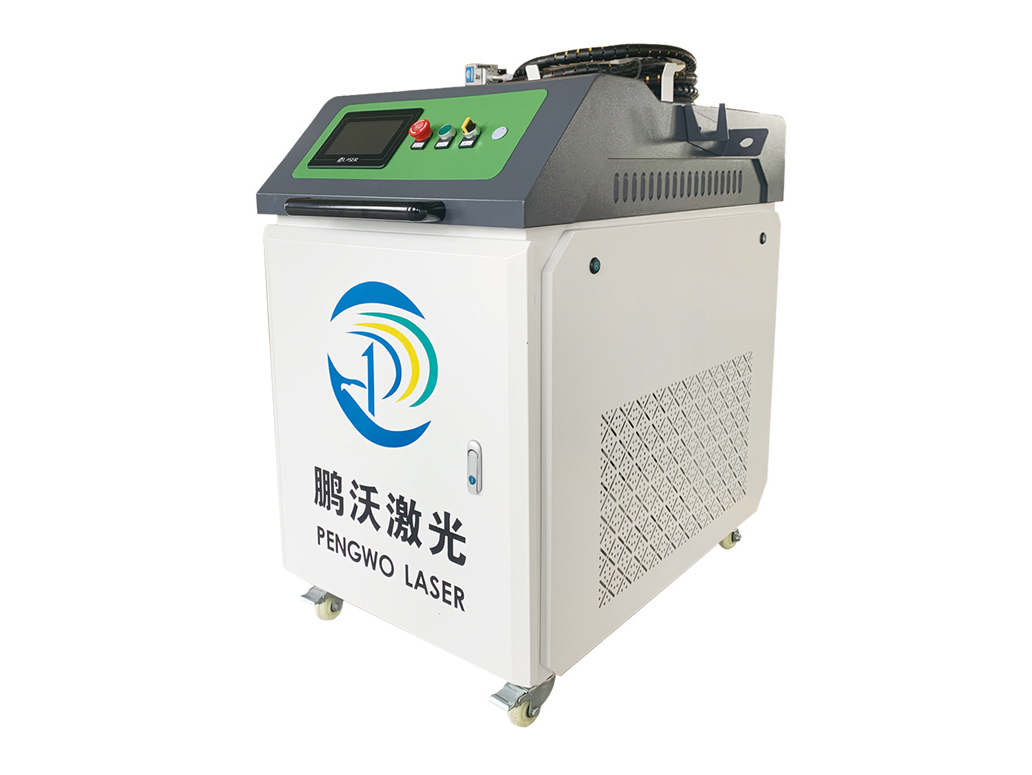

Handheld laser welding machine

Application industry

Suitable for mass automatic production of small, micro workpiece welding, mainly for thin wall materials, precision parts welding, can realize spot welding, stack welding, weld, seal welding.

Applied materials

1MM aluminum alloy welding, automobile hydraulic tank welding, pipe flange welding, ventilation pipe welding, advertising word welding, mandarin duck pot welding, window welding machine, frame welding, all kinds of models can be welded with different materials

Product analysis

Product advantage

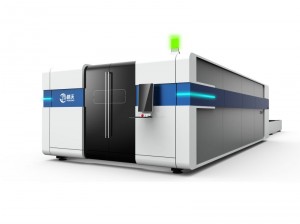

1. Powerful function: hole cutting, flying, frog jumping, automatic edge patrol and other functions

2. Easy to operate: bus control, wireless handheld, touch screen combination

3. Gantry double drive: very good steel, stability, cutting speed and machining accuracy

4. Intelligent numerical control system:Support multi-brand nesting software; Multi-language support; Auxiliary gas low pressure and cutting error alarm; Safety warning lights.

5. Automatic focus laser head: automatic focus function of the laser head, the focus can be automatically adjusted, without manual focus, software can automatically quickly replace different focusing mirror, meet the thickness of plate cutting, the operation is simple, convenient, fast and accurate. Large adjustment range: accuracy 0.01mm, suitable for different types of 0~20mm plate,Long service life: focusing components around the whole perimeter water cooling, to achieve high power, small volume, long-term cutting without heat, fog, improve the cutting head life.

6. Low COST/HIGH efficiency: preferred model for metal material processing, with fast cutting speed, low running cost, good stability and other characteristics

7. Imported servo drive, precision rack and piniona

Specification

|

No. |

Project |

Parameter |

||

|

1 |

device name |

Laser Handheld Welding Machine |

||

|

|

EWX Price |

|

||

|

2 |

Laser power |

1000W |

1500W |

2000W |

|

3 |

Operating Voltage |

AC220V/50Hz |

||

|

4 |

laser |

MAX |

||

|

5 |

welding head |

Shenzhen Kirin |

||

|

6 |

Size (mm) |

1200x680x1000 |

||

|

7 |

Machine weight (kg) |

120 |

||

|

8 |

Recommended welding thickness (mm |

0.5-3.0 |

||

|

9 |

Chiller |

Hanli Dual Temperature Dual Control Chiller |

||

|

10 |

Welding control system |

Shenzhen Kirin |

||

|

11 |

Welding speed range (mm/s) |

0-30 |

0-40 |

0-50 |

|

12 |

Wire Feeder |

Automatic wire feeding |

||

|

13 |

Feeding wire diameter (mm) |

0.8-1.6 |

0.8-1.6 |

0.8-1.6 |

|

14 |

Laser wavelength |

1080nm±5% |

||

|

15 |

Output cable length (m) |

10 |

||

|

16 |

Aiming and positioning |

red light positioning |

||

|

17 |

Maximum power consumption |

3.0kw |

4.5kw |

6.0kw |

|

18 |

Working environment humidity (℃) |

10-40 |

||

|

19 |

Working environment humidity |

<70% |

||

|

20 |

Power adjustment range (%) |

10-100 |

||

|

21 |

Weld requirements |

≤0.20mm |

||

|

22 |

Consumables |

protective lens, welding nozzle |

||

|

23 |

other |

full set of DLX electrical appliances |

||