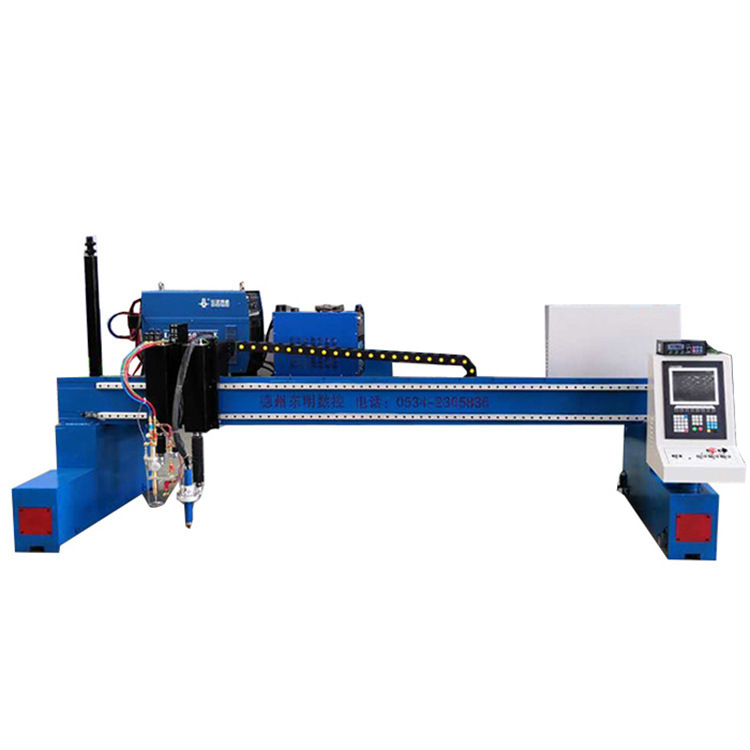

Manufacturer supply dragon gate flame cutting machine flame plasma cutting machine plasma cutting machine can be customized

Application Industry

Sheet metal processing, advertising sign word production, high and low voltage electrical cabinet production, mechanical parts, kitchenware, automobile, mechanical processing, saw blade, electronic parts, glasses industry, spring sheet, circuit board, electric kettle, medical electronics, hardware tools and other industries.

Cut sample

Performance characteristics

1. Beam: square tube structure, with good rigidity, high precision, light weight, small inertia characteristics. All welding parts are treated with vibration aging to remove stress, which effectively prevents structural deformation.

2. Longitudinal and transverse drive: precision rack and pinion (7 level precision) drive is adopted. The horizontal guide rail adopts the linear guide rail imported from Taiwan. The longitudinal guide rail is made of precision machined steel rail, which ensures the smooth running of the cutting machine, high precision, durable, clean and beautiful. Deceleration using planetary gear reducer, can be very perfect to ensure the accuracy and balance of motion;

3. Longitudinal drive frame (end frame) : both ends are equipped with horizontal guide wheel, can adjust the driving frame at the bottom of the eccentric wheel on the guide rail compression degree, so that the machine in motion to maintain stable guidance. Equipped with dust collector, at any time to scrape the accumulation of debris on the surface of the guide rail;

4. The lifting body adopts aluminum alloy structure, and the lifting guide adopts linear guide rail;

5. Easy to use automatic programming system, so that NC programming is no longer complicated, easy;

6. CNC control system adopts independent research and development control system, which has the best stability and strong anti-interference ability in China.

Product parameter

Cutting mode

Partners

Technical exhibition

Certificate of Honor