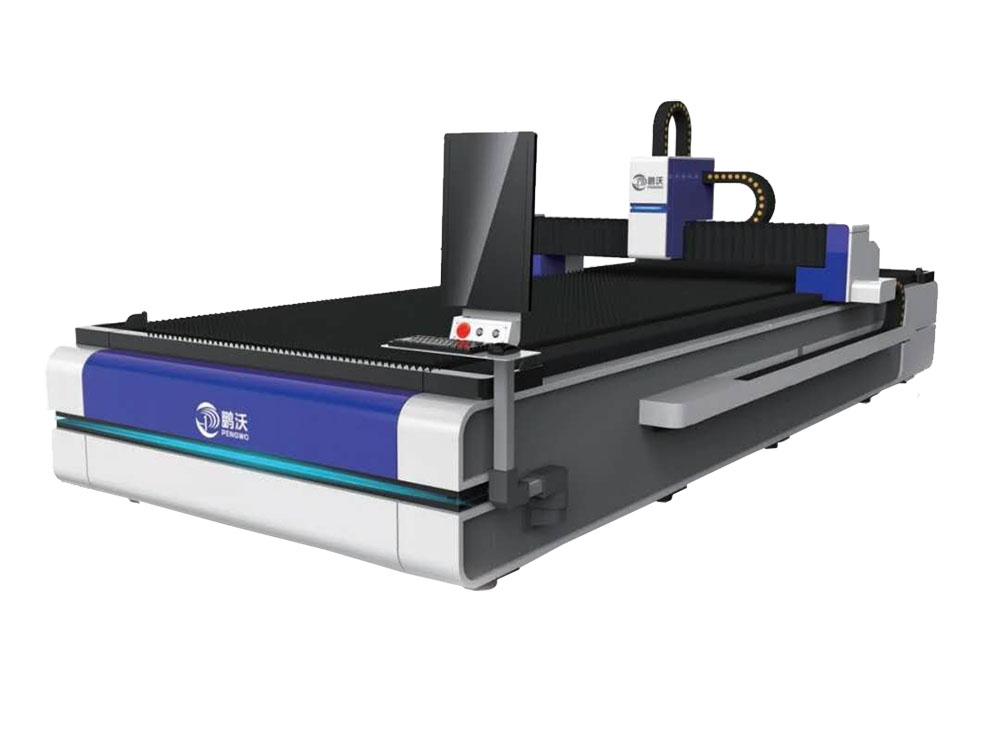

1560 mochini o bulehileng oa ho itšeha oa laser

kenyelletso e khutšoane ea sehlahisoa

● Mochini o le mong oa ho itšeha oa sethala o etselitsoeng tlhokahalo ea 'maraka oa lakane

● Mochine o na le bokhoni bo matla ba ho itšeha

● Litšenyehelo tsa ho sebetsa li tlaase haholo, botsitso bo babatsehang le ho ikamahanya le maemo ho matla

柏楚控制系统CypCut

Software ea ho seha maqephe e etselitsoe botebo ba indasteri ea fiber laser.E nolofatsa ts'ebetso e rarahaneng ea mochini oa CNC, 'me e kopanya li-module tsa CAD, Nest le CAM ho mojule o le mong.Ntho e 'ngoe le e 'ngoe ho tloha ho ho hula ho isa ho ho kenya ho ea ho seha e ka etsoa ke motho a le mong, .

Lintlha tsa Sehlahisoa

1. Bethe ea ho tjheseletsa e boima

Software ea ho seha maqephe e etselitsoe botebo ba indasteri ea fiber laser.E nolofatsa ts'ebetso e rarahaneng ea mochini oa CNC, 'me e kopanya li-module tsa CAD, Nest le CAM ho mojule o le mong.Ntho e 'ngoe le e 'ngoe ho tloha ho ho hula ho isa ho ho kenya ho ea ho seha e ka etsoa ke motho a le mong, .

2. Hlooho ea laser

E na le mefuta e mengata e fapaneng ea li-interface Settings, E nolofalletsa ho sebelisana le lisebelisoa tse fapa-fapaneng tsa fiber lasers.Optimized optical design, e kopantsoeng le li-sensor tsa digital haholo, e etsa hore ho itšeha ho sebetse hantle.Moqapi oa ho pholile ha metsi ka bobeli o nolofalletsa hlooho ea laser hore e sebetse ka ho tsoelang pele le ka ho tsoelang pele ka matla a phahameng. bakeng sa nako e telele.

3. Sebaka sa mosebetsi

Methōko e na le li-slider, tse thusang ho kenya boto haholoanyane le ho e sireletsa ho tloha ho mengoapo.Tafole e phahameng ea botsitso ea thipa, fokotsa ho kopana pakeng tsa thepa le tafole. Li-platform tsa Serrated le li-trim strips li nepahetse bakeng sa ho itšeha lakane ea tšepe,Sena se fokotsa spark spatter nakong. laser cutting.Modular design, E ka aroloa ka thoko ho boloka litšenyehelo tsa bareki.

4.Panele ea taolo

Phanele ea taolo e bonolo ebile e loketse.O ka khetha khabinete e arohaneng.Kapa o ka khetha ho hokela mochini.Panele ea taolo e kopaneng e ka potoloha likhato tse 180 ho isa ho tse 270,e boloka sebaka,Ho potoloha mahala ho hlokomela kopanyo lipakeng tsa motho le mochini.

5.Mohaho oa bethe ea lathe

Bethe ea sebopeho sa li-plate welding, khokahano ea skeleton, sebelisa khatello ea kelello ka botlalo, ka nako e ts'oanang, motsoako oa solder o tsitsitse, ka tlhahlobo e felletseng ea lintlha, ntlha e nepahetseng ea khatello ea maikutlo le sebopeho sa tšehetso lia fihlelleha. ka phekolo ea botsofali, e fokotsang haholo khatello ea kelello ea ka hare ea bethe.Ho netefatsa ts'ebetso e tsitsitseng ea nako e telele ea sesebelisoa.

Tlhaloso

LBH

Phapang pakeng tsa mochini oa ho itšeha oa laser le mochini oa ho itšeha oa plasma

1. E sebetsa ka tsela e fapaneng

Mochini oa ho itšeha oa laser ke laser e hlahisoang ke laser ka sistimi ea optical e tsepamisitsoeng ho beam ea matla a phahameng a matla a laser.

Lebone la laser le khanyetsa holim'a sebaka sa mosebetsi, e le hore sesebelisoa se fihle sebakeng se qhibilihang kapa se belang.

Ka nako e ts'oanang, coaxial e nang le khatello e phahameng ea khase e nang le sehlaseli e senya tšepe e qhibilihisitsoeng kapa e nang le mouoane.

E le ho finyella sepheo sa ho khaola.

Melemo le go tlhoka mesola ea laser ho itšeha mochine

1, melemo ea mochini oa ho itšeha oa laser:

(1) Lebelo la ho itšeha Laser: lebelo la ho itšeha la sheet ho fihlela ho 10m / min, le phahame haholo ho feta mochini oa ho itšeha oa plasma.

(2) boleng bo phahameng ba ho itšeha: deformation e nyane, tafole ea ho itšeha e boreleli.Laser cutting groove e nyane haholo, sebaka se sehang sa laser ntle le ho sila se ka sebelisoa ka kotloloho bakeng sa welding.

(3) Ho nepahala ho phahameng: ho nepahala ha mochini oa laser ho fihla ho 0.05mm, pheta ho nepahala ha boemo ho fihlela ho 0.02mm.

(4) lisebelisoa tsa laser ho itšeha mefuta e mengata ea likopo: lisebelisoa tsa tšepe le tse seng tsa tšepe li ka ba.Ho na le mechine ea ho itšeha ka laser ea tšepe le mechine ea ho itšeha ea laser ea CO2 e loketseng lisebelisoa tse seng tsa tšepe.

(5) Laser e ka boela ea sebelisoa bakeng sa ho betla, ho cheselletsa, ho cheka le mesebetsi e meng e matla.

Melemo le melemo ea mochini oa ho itšeha ka plasma

1, melemo ea mochini oa ho itšeha oa plasma:

(1) Molemo oa mochine oa ho itšeha oa plasma ke hore matla a plasma arc a tsepamisitsoe haholoanyane, mocheso o phahame, lebelo la ho itšeha le potlakile, deformation e nyenyane, empa hape e ka khaola tšepe e sa hloekang, aluminium le lisebelisoa tse ling.

(2) Mochini oa ho itšeha ka plasma o na le molemo oa ho khaola lipoleiti tse teteaneng, hobane ka mokhoa o teteaneng oa ho itšeha, o ka finyella lebelo le phahameng haholo la ho itšeha, le phahameng haholo ho feta laser le lelakabe.

Single sethaleng seha carbon tšepe poleiti seha nozzle futhumatsang mokhoa oa ho sebetsana le, sesosa ke eng?

Mabaka a ho futhumatsa carbon steel:

1, phallo ea khase e nyane e nyane, e ke ke ea pholile ka botlalo holim'a nozzle ea koporo.Khase e phahameng ea naetrojene e ka sebelisoa e le khase e thusang, phello ea pholiso ea naetrojene e nang le khatello e phahameng e ntle.

2. Ha ho nozzle ea koporo e sebelisetsoang khase e pholileng.HO FIHLELA khase e pholileng ea molomo oa koporo e ka fokotsa mocheso oa molomo oa koporo.

3, ho itšeha haholo, laser ho bonolo ho otla nozzle e nyane, e le hore nozzle e futhumale.Hoa hlokahala ho lokisa ho tsepamisa maikutlo kapa ho eketsa bophara ba nozzle ha molomo o sa chese.

4, tšepe ea carbon ha e seha, karabelo ea oxidation, e hlahisa mocheso o mongata.Boemo bona bo ke ke ba qojoa, 'me sebaka se pakeng tsa molomo le thepa se ka fetoloa ka nepo.

Ho seha laser ho sebetsa joang?Ke eng?

Theknoloji ea ho itšeha ea laser e sebelisoa haholo ha ho etsoa lisebelisoa tsa tšepe le tse se nang tšepe, e ka fokotsa haholo nako ea ho sebetsa, ea fokotsa litšenyehelo tsa ho sebetsa, ho ntlafatsa boleng ba mosebetsi.

Pulse laser e loketse lisebelisoa tsa tšepe, laser e tsoelang pele e loketse lisebelisoa tse seng tsa tšepe, ea morao-rao ke tšimo ea bohlokoa ea ts'ebeliso ea theknoloji ea laser cutting.Laser ea kajeno e fetohile "sabole" eo batho ba lorang ho e phehella.